Automotive Industry

Acres, Solutions Provider to the Automotive Industry

You too can benefit from working with Acres, a supplier focussed on value-add and continual improvement. We understand the speed in which the industry moves and the key drivers.

Key Drivers

Automotive customers benefit from a supplier that understands just in time and how important every second is when manufacturing a car.

It is fast paced, and can be greatly impacted by delays if equipment fails. Even in the most sophisticated and advanced assembly lines there are still manual operations required to deliver components and present them in the right orientation for unloading and to despatch in the correct batch size. Whilst majoring on production, the automotive sector is highly focussed on ergonomics, safety and quality.

-

Saving seconds in a process has a huge impact.

-

Component protection and quality is critical.

-

Team engagement & ergonomics is key to success.

Expertise

We specialise in the design and fabrication of equipment that is used in the manufacturing process, such as flow racks, AGV dollies, tow-trains, assembly dollies stillages, trolleys etc.

The products we deliver into the automotive sector aim at improving quality, team member ergonomics and process ‘takt’ time. This can be anything from kitting media to deliver components from a logistics sequencing centre to a production build line; all the way to semi-automated equipment for carrying out specific operations. We harness our knowledge, experience, technology, intellectual property and a belief in continual improvement to offer a complete service that stands apart from other companies of our nature.

-

World class product design.

-

AGV integration, tow-trains & stillages

-

Multi-sector solutions

Expert Insight

Question and Answers with Automotive Industry Insider Paul Kirkley — Kaizen Group Senior Leader.

Toyota Motor Manufacturing Ltd is the British manufacturing subsidiary of Toyota. The main factory is at Burnaston in Derbyshire.

- Tell us about yourself- Who is Paul? When you aren’t working, what do you like to do to relax?

- Total relaxation for me is spent away on holiday with my wife reading a book and listening to music. In my spare time I manage, promote and put on shows for some great bands and artists. Check out your local music scene, I am convinced you would be impressed!

- What has been the biggest achievement that you are most proud of?

- My greatest inspiration are my wife and children. Despite the many obstacles life has thrown at them, they are the most beautiful, hardworking, inspiring individuals that I have the pleasure to know. In terms of my music, I have recently completed a successful 10 date UK tour with one of my artists. A real bucket list achievement.

- Why did you choose to work in the Automotive industry? What drew you towards it?

- I have always had a passion for cars. I left school and worked for 14 years in the automotive accident repair sector, moving on to Toyota Motor Manufacturing (UK) Ltd (TMUK) in 1998 in their paint department. 25 years later I am still here working with great colleagues and friends.

- How would you describe your job role at Toyota

- I have been fortunate enough to have varied job roles since joining Toyota. Progressing from a fresh faced employee on the production line to managing a team of 28 employees. Through to working on new model projects and implementing kaizen (continuous improvement) through the application of the Toyota Production System (TPS). I am also a licenced ‘Toyota Institute’ trainer of TPS & Kaizen and through this, really enjoy developing others

- What are you most passionate about in the Automotive Industry?

- One of the key Toyota beliefs is ‘Respect for people’ and this is embedded in the company DNA as well as my own. Through effective team working and using TPS tools to visualize opportunity, anything is possible. Then when you can see opportunity and you are given the support to improve. It is a great motivator. I have been through this cycle many times and been energised by the process. As a result, I am passionate about sharing this with others and guiding them through the process to make our production methods better, smoother and more efficient.

- Have there been any new developments that you are excited about?

- I believe that the hydrogen fuel cell Toyota have developed can offer a significant solution in terms of zero emissions mobility. Just like Hybrid in in 90’s, I believe Toyota will lead the way in hydrogen fuel cell product innovation.

Our Automotive History

Situated at the centre of the midlands manufacturing hub, Acres was one of the first suppliers when Toyota (TMUK) established their new factory at Burnaston, Derbyshire.

Toyota and Motorola pioneered the concept of ‘Lean Engineering’ which is at the heart of all Toyota’s activities. Since that introduction ‘lean’ has become part of Acres DNA and is applied in all the industrial markets it serves. Acres extended its technical and commercial offerings and supplies product to Jaguar Land Rover and through other partnerships to Mini UK.

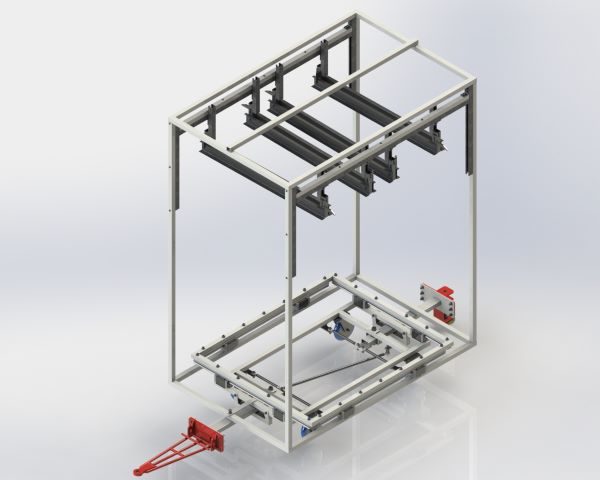

Case Study - Satisfy the needs of a major car manufacturer in replacing an old and cumbersome parts handling system with a bespoke concept and technology.

The car manufacturer had for years a parts moving and handling system powered by pneumatics and hydraulics. It was now taking up too much space within the car plant and was proving to be expensive to repair and maintain on a regular basis. Being a Japanese car manufacturer, they challenged Acres to develop from scratch a Japanese process known as karakuri – the use of mechanical devices to create movement. In this instance, the factory uses karakuri to transfer parts from a moving device to a rail by the use of a simple mechanical interface allowing the parts to move or stay in position till movement was desired.

With no full certainty of a successful outcome, Acres engineering agreed to research the Karakuri principle. Using 3-D CAD modelling; and based on previous similar products a satisfactory outcome was achieved.

This project posed many unforeseen challenges in attempting to replace a tried and tested parts handling system already in existence. Many ideas and proposals were considered in considering a potential and unique solution. Doubt and uncertainty was evident from the outset given the scale of the project, transferring newly moulded car instrument panels directly from the fabrication plant seamlessly into the assembly areas. Further doubts existed as to whether or not Acres Engineering could develop a transport and delivery methodology that would operate over long periods of time and on a consistent basis.

They therefore had many technological concepts to consider in developing the ergonomics and modularity of this turnkey project. Other considerations centred on dimensional accuracy and compliance to quality and safety standards that this car manufacturer was insistent upon.

Centred on the concept of karakuri and their previous use of combinations of metals and frictionless materials, they began to create a framework that solely operated on gravity as its source of motion and movement. This would entail several aspects mirroring the materials flow from the moulding plant to the assembly line. From lengthy discussions and the extensive use of CAD to theorise and detail potential solutions, Acres Engineering began to experiment with the front runner of all their concepts.

A trolley was conceived as the best possible method of starting the process. It would be loaded at the mould plant and when full, moved to the main line and connected to the framework that would move the parts into assembly. This connection was a critical part in the entire process as any misalignment at the joints would interfere with the functionality of the transfer of parts.

Prototypes were produced from concepts of both the trolley and the main framework and a very lengthy testing regime was undertaken in order to prove the concept. Every aspect of the principle was challenged, from the exacting geometry of all of the framework to the method of seamlessly connecting the trolley to the frame.

The most challenging aspects were the methods of moving the parts along the line from start to finish without any form of mechanical or human intervention. The concept involved the use of a four rail system with each rail having a friction free strip of durable plastic as its main runner. This was also replicated on the trolley. The trolley would be wheeled up to the framework and the loading began. By gravity alone, the parts, suspended on hangars, would transfer onto the mainframe rail system.

The ingenuity and technological knowhow of the company had led to the development of a totally new concept for them using gravity to manipulate the rails in such a way that the hangers were returned to the start once the parts had been removed. This involved a great deal of testing, using the prototype with different weights taking the place of the moulded parts in order to determine the optimum operational length and angles of the rail system. At the end of the rails was a pulley system, cleverly developed from concept to prototype that automatically altered the pitch of the rails from down to up in order to engineer the return of the empty hangers.

Extensive testing and fine tuning took place before the concept was presented to the client. Acres Engineering had to be assured that the concept would stand up to the scrutiny of the customer before any orders would be received.

The system has been adopted by the customer and is now fully operational.

This project was highly innovative and provides significant improvements in cost savings and production efficiencies.