Supercars

Acres, Solutions Provider to the Supercar Industry

You too can benefit from working with Acres, a supplier focussed on value-add and continual improvement. We understand the speed in which the industry moves and the key drivers.

Key Drivers

Supercar manufacturers benefit from a supplier that understands the value, and importance of each component.

The super car industry is one of the most vibrant and innovative industries. It is comparable to the top entry level of the smartphone industry, where the leading companies are racing for competitive advantage – pushing the boundaries in specification and looking to provide the ultimate exclusive supercar. A huge amount of time and effort goes into the design and manufacture of each component, to the point where some components become a piece of art in their own right. With such high value, long lead time components, it’s critical that they are protected and delivered damage-free to the build line in the right sequence and orientation. This is what Acres does best.

-

Reducing stop time

-

Improving flow

-

Customer centric approach

Expertise

Acres specialise in kitting media and production support equipment aimed at driving quality, health and safety, and productivity improvements.

The products improve how materials and sub-assemblies are handled, ensuring that parts are presented in an efficient and ergonomic way. Acres products typically improve visibility and allow for any problems to be identified sooner in the process. They are particularly strong on standardisation, and sustainable, modular solutions.

One of the Speedtail projects that Acres worked on with McLaren was the P23 Rear Bodyside Stillage. No ordinary stillage, as it was designed to transport, protect and present the biggest carbon fibre part ever designed by McLaren. The teams from McLaren and Acres had a project kick off meeting to discuss the critical areas of the component, where it could be supported and which surfaces maybe at increased risk of being marked. It was critical to hold the part in a way that would prevent damage, whilst presenting it in the most efficient way for the McLaren logistics and production teams. It is this passion for joint success and continual improvement that makes the McLaren – Acres relationship so special. The strength of the relationship is that Acres have become an extension of the team and share the excitement for the future vision. As the McLaren team huddled around the screen to watch the Speedtail vs the F35, so did Acres!

-

World class product design.

-

Reducing damage

-

Improving productivity

Expert Insight

Question and Answers with Supercar Industry Insider Andrew Boothroyd, Head of Logistics Engineering and Future Solutions.

McLaren Automotive is a British automotive manufacturer based at the McLaren Technology Centre in Woking, Surrey.

- Tell us about yourself- Who is Andrew? When you aren’t working, what do you like to do to relax?

- I own two Labradors, so my weekends are usually spent on long walks, out in the countryside getting plenty of fresh air. When I don’t have the dogs with me, I like to be out on my mountain bike, not necessarily up a mountain, just off the beaten track, away from the hustle and bustle of the UK’s busy roads. It’s where I get the chance to think and when I’m free to think, I get the opportunity to innovate. My team hate it when I go away on holiday because I always come back to work feeling energised with lots of new ideas.

- What has been your biggest achievement that you are proud of?

- Every new car launch is a huge achievement for everyone involved in the project. Recently there have been a few of them, 570S Spider, 720S Spider, GT, 600LT, 620R, 765LT, Senna, Senna GTR, Speedtail, and Elva.

- When was your first introduction to the Supercar industry and why did you choose to work in the Supercar industry? What drew you towards it?

- I made the move from Aerospace to Automotive three years ago. Having spent over 15 years in the aviation industry, I was keen to try something different. The technology, design, engineering and materials used to build a modern Supercar are very similar to those used to build and maintain an aircraft. The challenges of managing the supply chain are also similar, especially when you are pushing the boundaries of technology. My biggest draw to Supercars was the ability to work with people who are passionate about developing the latest technology and using it to push engineering boundaries.

- Why the quality of equipment used in the Supercar is so important?

- I always remember being told that when you fly an aeroplane you cant just pull over at the side of the road if it breaks down, in a way, the same is true for a Supercar. When you are heading towards a corner at 200mph, you are committed and have an expectation that the car is going to handle in a predictable way. As much as I like working on cars, the real fun is when you are out on the tarmac, not when you are sat in the garage waiting for parts.

- What are you most passionate about Supercars?

- Driving a Supercar is an experience. There is a build-up of nervous energy that you feel as you exit the pit lane, a sense of adrenaline as you brake for the first corner and the connection you feel as you build up your knowledge of the car, the track and the prevailing conditions. The more you practice, the more familiar you become, the faster you want to go, the later you want to brake. After a while, it becomes addictive, the sounds, the smells, the noise and before you know it, you’re hooked. You don’t have to own a Supercar to experience one, there are numerous ways to get involved in track days and motorsport. You can always dream that one day there might be a Supercar parked on your driveway (even if it is only for the weekend).

- Have there been any new developments that you are excited about?

- Over the years, manufacturers have pushed the development of power and ultimately, top speed. However, powerful engines are heavy and if you want to experience driving a car at 200mph plus, you’ll need a very long stretch of straight road. Now, the focus is changing to saving weight and increasing torque. I’ve always been a fan of the V6 engine and I hope to see the V6 become the engine of choice for the next generation of Supercars. It’s also great to see Supercar technology and materials being made available on standard road cars.

- What do you see as the immediate priorities for the industry are there any challenges that the Supercar industry faces??

- The automotive sector is going through a great deal of change at the moment. 2020 has been challenging with the reaction to a global pandemic that has seen factory closures and local lockdown restrictions in pretty much every region of the globe. The 1st January 2021 begins the outcome of the Brexit transition and we are yet to see the impact that will have on the UK’s ability to import and export products and services. Decarbonising transport is a high priority, with the EU recently agreeing new standards that will see us reduce 2021 carbon dioxide emissions by 15% by 2025 and by 37.5% by 2030. Digital technology will also be a big theme over the next ten years as Industry 4.0 drives further innovation in how we design, manufacture and drive modern vehicles.

- How has the Supercar industry been affected by Covid?

- Allowing customers to experience the cars safely is a top priority. Having access to dealerships and repair centres is just as important to a Supercar owner as any other car driver. Like most manufacturing industries the biggest challenge is managing the supply chain. The automotive industry is dependant on a global supply chain, reliant on suppliers large and small to deliver parts just in time. Now more than ever, we must all work together to support each other to deliver on our commitments.

- What do you think the future looks like for the UK Supercar industry and do you have any predictions of new equipment changes/ requirements in the years to come?

- Predicting the future is always a challenging part of the job. Electric power supply and infrastructure is a big theme at the moment. It’s important to start thinking about how and where you will charge your car (at work, at home, when you go out, at the track etc.). Another priority is the management of hybrid batteries throughout the lifecycle, from the supply of raw materials to the safe disposal, recycle or reuse of old batteries. I think out on the track we will see the uptake of alternative fuels whilst battery technology continues to be developed. Another significant change is understanding the customer of the future, what their expectations will be and how we manage their digitally enabled driving experience. Personally, I expect to see a huge rise in simulator technology, the ability to experience different cars and tracks in a virtual world. I’d also like to see the development of autonomous driving on the track. I can’t wait to have the opportunity to experience a fast lap in a car that is driving itself.

Our Supercar History

Acres has a long history of relevant experience, combining and transferring its knowledge/ best practice from the Aerospace and Automotive sectors to the Supercar sector.

Although Supercars fit within the automotive sector, they are certainly different to mass produced cars. They are hand built machines of the highest levels of precision and quality. Acres has the benefit of substantial experience working in the Automotive and Aerospace industries. Combining this knowledge and experience Acres was able to easily transfer into the Supercar sector and add considerable value. Acres now has a history working with a range of Supercar companies in the UK.

Case Study -

The McLaren Elva is different and its topless. The fifth addition in the ultimate series and inspired by designs developed by Bruce McLaren.

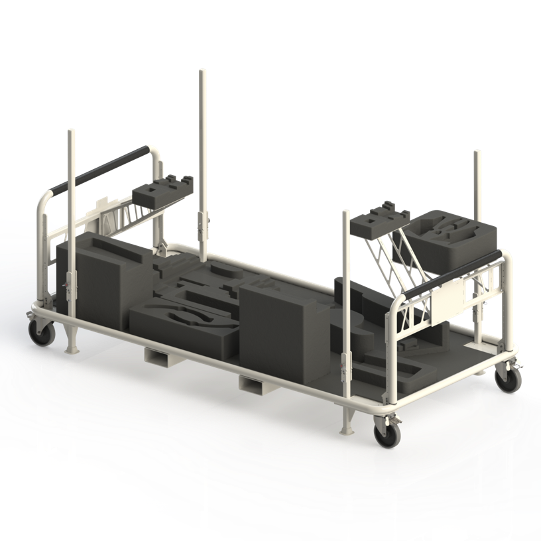

A painted parts stillage was required to transport complex body parts from the paint shop to the production line. A straightforward request, but what about the specification? Production space is a premium. Reducing waste and re-using support equipment was important to future development. These imperatives had to be taken into account with the design and functionality of the stillage.

The stillage follows McLaren’s existing tubular systems and in line with reducing waste and space, the posts and arms are collapsible, making the bodies stackable, reducing storage space. The parts holders can be replaced giving the flexibility to re-use the stillages for future development.

To maximise functionality the four stillage castors can swivel and are individually braked.