Acres Expands its Capability with Water Jet Cutting

New Investment, New Capability, WATER JET CUTTING arrives at Acres Engineering…

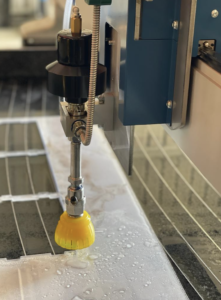

We are excited to announce and launch our new water jet cutting capability! This new investment in a Swift-Cut water jet cutting machine will further help us to have greater control over processes, cost and lead time.

This investment is a further step in Acres business transformation plan that’s seen substantial investment and organisational changes within the business to drive efficiency improving our cost and lead time.

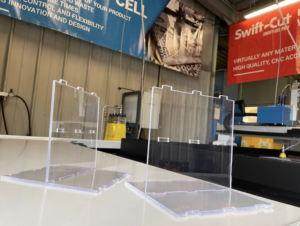

Swift-Cut commissioned the new waterjet machine this week and our CNC team have already produced a number of components for incorporation into our products.

Our clients see a lot of potential for this machine capability and already have 35 days of cutting queued up!

The machine offers a whole host of benefits:

- Cuts almost all materials – all reflective material (i.e., brass, aluminium) and heat sensitive materials (i.e., plastic, rubber, wood or composites) can be cut by abrasive waterjet cutting technique.

- Low environmental impact – no toxic fumes and smoke; no harmful radiation.

- Produces a clean, smooth cutting edge.

- No heat exchange is loaded on the workpiece. Hence, there is no change in the material structure due to heat.

Thank you to the Team at Swift-Cut for manufacturing and commissioning an impressive machine and delivering a fantastic service along with way.

#SwiftCutAutomation #WaterjetCutting #SwiftCut #SwiftJetPro #Investment #NewCapability #ContinualImprovement