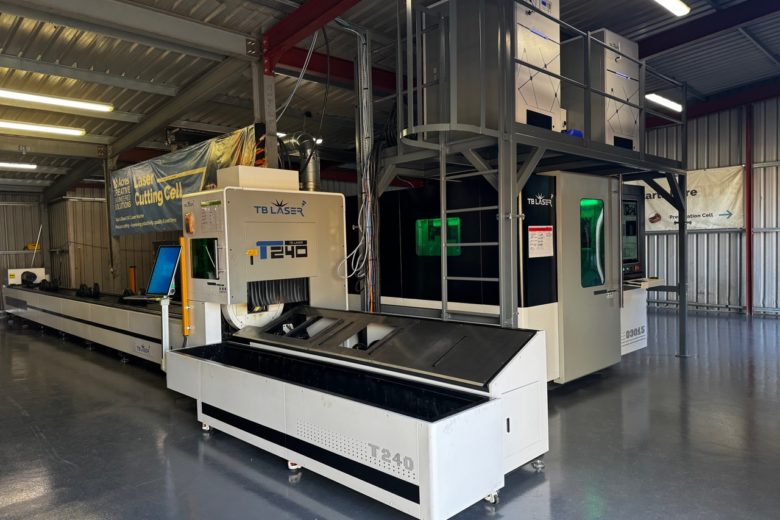

Capital Investment Equipment – Live and Kicking!

We have made a capital investment in our Prep Cell as part of our Vision25 project. Phase one of the project has seen us replace our 1.5kw combi laser cutting machine with two individual 3kw machines – one sheet laser with exchange table and one 9m tube cutter.

This project will has delivered and will continue to deliver numerous benefits to our employees and customers…

|

Improvement to our Safety

|

Safety will be enhanced by transitioning from an open machine to fully enclosed machines, which improves operator safety and the efficiency of the LEV extraction system.

|

| Improvement to our

Quality |

Upgrading from 1.5 kW to 3 kW machines will result in better finishes and greater accuracy in the cuts. We will no longer need to say, “Scotty, we don’t have the power.”

|

| Improvement to our Capacity | The capability to operate two machines simultaneously (sheet and tube) while also loading and offloading material during sheet laser cutting (via the exchange table) will significantly increase the number of components we can cut each day. This eliminates the need to choose between sheet or tube.

|

| Improvement to our Capability |

We will have the capability to cut thicker materials, including stainless steel and aluminium, rather than being limited to mild steel. Additionally, our tube cutting capacity will increase from 6 meters to 9 meters.

|