How do co-bots and MHE work together in a Manufacturing Facility?

Acres Engineering is the UK’s leading fabricator, specialising in designing innovative solutions that seamlessly integrate with co-bots, robots, and AGVs. Our bespoke material handling equipment and systems optimise automation, enhancing productivity and safety across warehouse and manufacturing environments.

How Do Co-Bots and MHE Work Together in a Manufacturing Facility Setting?

In the world of manufacturing, the synergy between collaborative robots (co-bots) and Material Handling Equipment (MHE) is transforming production floors. This integration brings increased efficiency, enhanced safety, and cost-effectiveness, supporting both human workers and machines in ways that were once unimaginable. Today, let’s explore how co-bots and MHE complement each other within manufacturing facilities to optimise processes and create a more agile production environment.

Understanding the Role of Co-Bots and MHE in Manufacturing

Co-bots are collaborative robots specifically designed to work alongside humans, supporting tasks that require high precision and repetition. Unlike traditional robots, co-bots are compact, flexible, and equipped with safety features that allow them to share space with human workers. They’re commonly used in tasks like assembly, quality inspection, and sorting, as well as lightweight material handling.

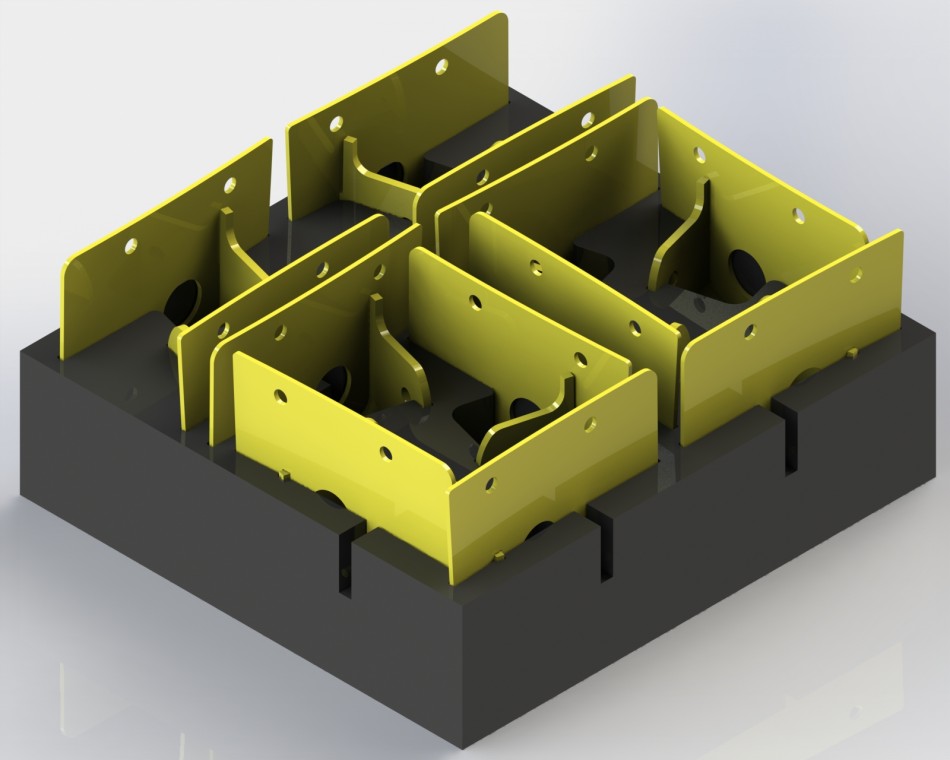

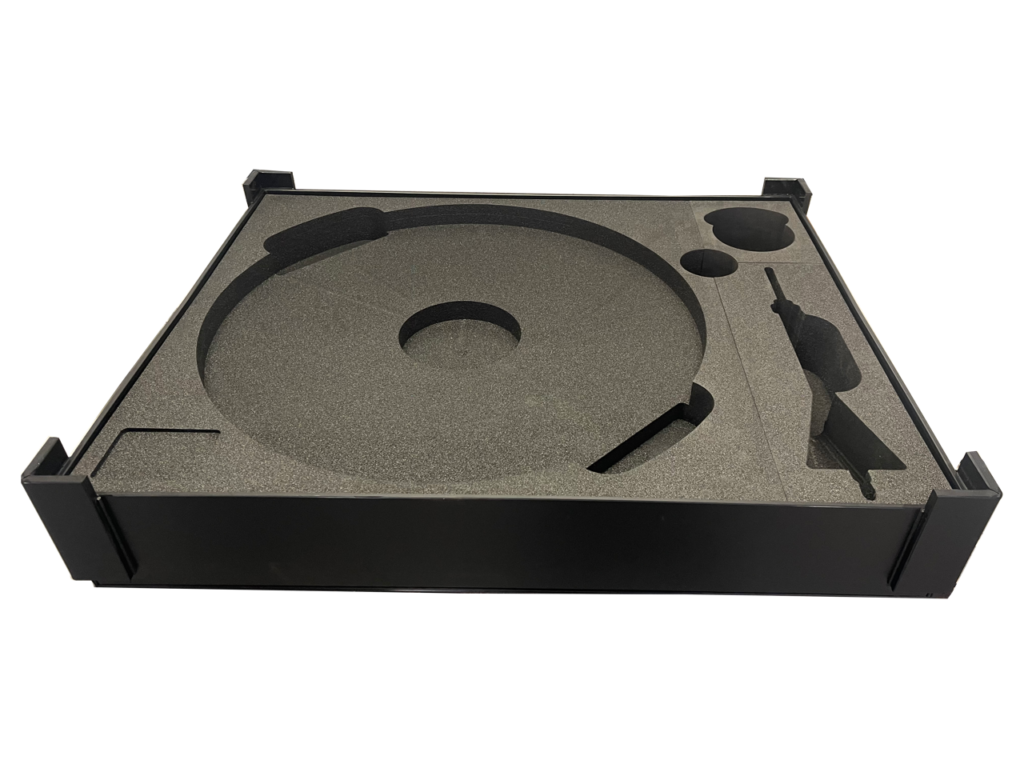

Material Handling Equipment (MHE) especially the solutions we design at Acres Engineering, includes a wide range of machinery and tools that streamline the movement, lifting, and organization of materials within a manufacturing facility. From stillages, trolleys, kanban systems, pick – place solutions, tooling holders etc, our MHE is specifically crafted to complement co-bots, reducing physical strain on workers and optimiSing the overall flow of goods and materials.

In a manufacturing facility, these two technologies together create a powerful system that optimises production flow, minimises downtime, and supports human workers by taking on repetitive and physically demanding tasks.

How Co-Bots and MHE Work Together in Manufacturing

The integration of co-bots and MHE in manufacturing creates a seamless process where both machines and workers can thrive:

- Enhanced Task Specialisation:

- Co-bots are ideally suited for repetitive and precise tasks like assembly, quality checks, and part sorting. They can manage small items with speed and accuracy, reducing errors and improving quality control.

- MHE handles the bulkier, heavier items on the production line, transporting components between workstations, loading docks, and storage areas. By leveraging the strengths of each, manufacturers can create a balanced workload and reduce bottlenecks.

- Increased Safety and Ergonomics:

- Co-bots and MHE contribute to a safer working environment by taking on the physically demanding or repetitive tasks that could lead to worker injuries over time. Co-bots relieve workers from repetitive motions like reaching and placing, while MHE eliminates the need for heavy lifting or awkward manoeuvres.

- This partnership reduces the risk of injuries, allowing human workers to focus on higher-level tasks that require critical thinking and problem-solving, ultimately improving ergonomics and worker satisfaction.

- Optimised Speed and Efficiency:

- By combining the precision of co-bots with the heavy-duty capabilities of MHE, manufacturing facilities can significantly improve workflow speed. Co-bots work at high speeds on tasks like assembly and inspection, while MHE ensures that materials are always available where they’re needed.

- This integrated approach minimises downtime, keeps production moving seamlessly, and boosts output, helping manufacturers meet tight deadlines without sacrificing quality.

- Data-Driven Process Optimisation:

- Co-bots and MHE, often equipped with smart sensors and data-sharing capabilities, can collect and relay real-time data about inventory levels, equipment status, and production flow.

- By analysing this data, facility managers can identify inefficiencies, anticipate maintenance needs, and make informed adjustments to scheduling or equipment usage, optimising resource allocation and minimising waste.

Real-World Applications of Co-Bots and Acres Engineering MHE

Here’s how co-bots and Acres Engineering’s MHE work together to solve common manufacturing challenges:

- Assembly Lines: Co-bots handle detailed assembly tasks, ensuring quality and precision. Our MHE solutions—like lifting trolleys or custom conveyance equipment—move completed sub-assemblies to the next station, ensuring a continuous workflow.

- Quality Control: Co-bots equipped with sensors inspect products for defects, while our ergonomic MHE moves the inspected items to designated areas for further processing or packing, supporting an efficient and consistent quality control process.

- Parts Supply and Replenishment: Co-bots monitor parts usage on the line, signaling when stock needs replenishing. Our MHE solutions quickly transport components or materials to the right stations, preventing any interruptions in production.

- End-of-Line Packaging and Palletising: Co-bots perform detailed packing tasks, while our custom-designed MHE systems transport packed items to palletising areas and onto loading docks, making final dispatch efficient and streamlined.

Benefits of Co-Bots and MHE Integration in Manufacturing

Integrating co-bots and MHE within manufacturing facilities provides a host of benefits, from operational efficiency to cost savings:

- Reduced Labor Costs: Co-bots and MHE take on labor-intensive tasks, allowing human workers to focus on higher-value roles. This reduces the need for overtime and increases productivity.

- Higher Worker Morale: With repetitive and physically demanding tasks handled by machines, workers experience less strain and fatigue, creating a safer, more engaging workplace.

- Improved Quality Control: Co-bots perform precise, repeatable tasks that minimise errors, enhancing the quality and consistency of products. By using data insights from co-bots and MHE, manufacturers can fine-tune processes to reduce waste and meet quality standards.

Looking Ahead: The Future of Co-Bot and MHE Integration in Manufacturing

As automation technology advances, the collaboration between co-bots and MHE in manufacturing facilities will only strengthen. With continuous developments in artificial intelligence, smart data analysis, and machine learning, the future of manufacturing is all about creating an agile, responsive, and data-driven environment.

At Acres Engineering, we’re committed to supporting manufacturers with custom-designed MHE solutions that integrate seamlessly with co-bots and other automation technologies. Together, co-bots and MHE create a smart, safe, and efficient production space, positioning manufacturers to meet industry demands and remain competitive in a rapidly evolving landscape.

By embracing this collaborative approach, manufacturers can optimise their operations, improve worker safety, and build a sustainable production environment that’s ready for the future.

Acres Engineering is the UK’s leading fabricator, specialising in designing innovative solutions that seamlessly integrate with co-bots, robots, and AGVs. Our bespoke material handling equipment and systems optimise automation, enhancing productivity and safety across warehouse and manufacturing environments.

Acres have a range of standard products but also support clients with custom machinery and medium-high volume products such as trolleys, stillages etc.

We have manufactured lots of different tables / workstations / workbenches for various industries.

We also manufacture access platforms, jigs and fixtures and many other types of production support solutions / products.

Talk to us today about your requirements: [email protected] / 01332695240 / Contact Us Form

Click on the icon to check out our social media! Please follow, like and share!

Want to know more about Acres Engineering?

We are based in the UK from our Headquarters in Derbyshire, England and have a European office in Malaga, Spain within the EU.

Find out more about where we have been and what we have been up to by checking out our latest blog posts.

Take a look at how we support of the Armed Forces, STEM/Schools and Charities.

As a world leader in our field, we offer a range of information guides sharing best practice with our clients.

We make it easy to engage with us, we are approved on: EcoVadis (external) / JOSCAR (external) / AVETTA (external) / COUPA (external) / SAP ARIBA (external) / DEEPSTREAM (external) ….you can download our BSI / Insurance certificates here.

![]()

![]()

![]()