How do co-bots and MHE work together in a warehouse setting?

Acres Engineering is the UK’s leading fabricator, specialising in designing innovative solutions that seamlessly integrate with co-bots, robots, and AGVs. Our bespoke material handling equipment and systems optimise automation, enhancing productivity and safety across warehouse and manufacturing environments.

How Do Co-Bots and MHE Work Together in a Warehouse Setting?

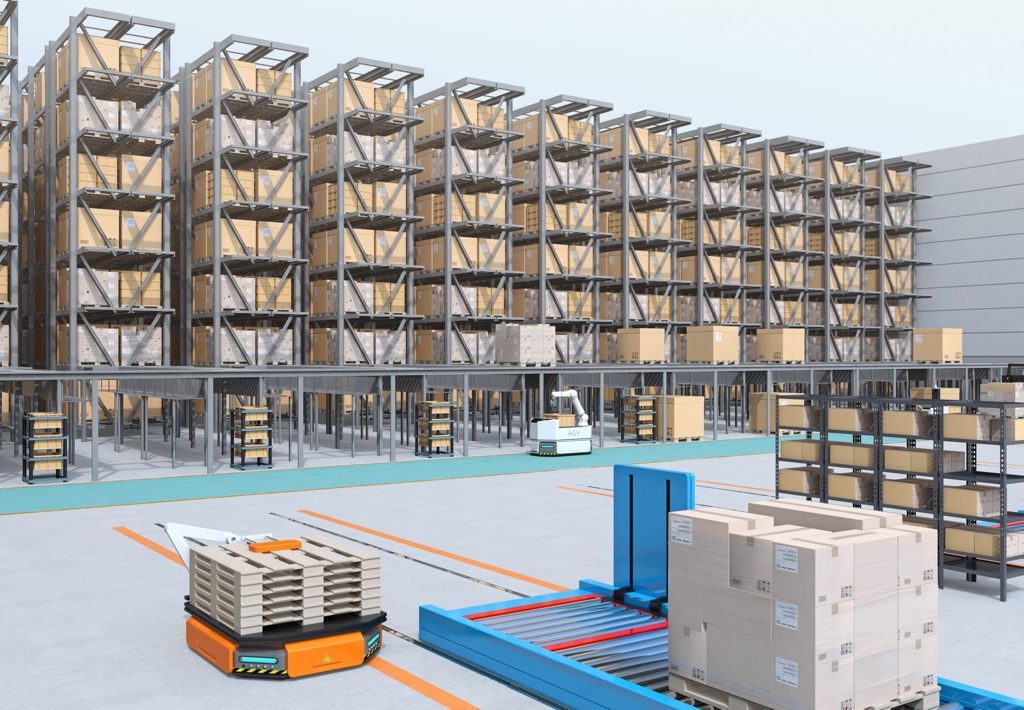

At Acres Engineering, we understand that efficient and safe warehouse operations are key to meeting today’s fast-paced logistics demands. Specialising in the design and manufacture of custom manual handling equipment, we’re dedicated to creating solutions that work seamlessly with collaborative robots (co-bots) to transform productivity in your warehouse. Let’s explore how co-bots and MHE, specifically designed for this purpose, can work together to revolutionise warehouse workflows.

What Role Do Co-Bots and MHE Play?

Co-bots—collaborative robots designed to operate alongside human workers—excel at precise, repetitive tasks like picking, sorting, and packaging. Unlike traditional robots, co-bots are compact, agile, and equipped with sensors, making them safe and adaptable partners for both humans and machinery in tight warehouse spaces.

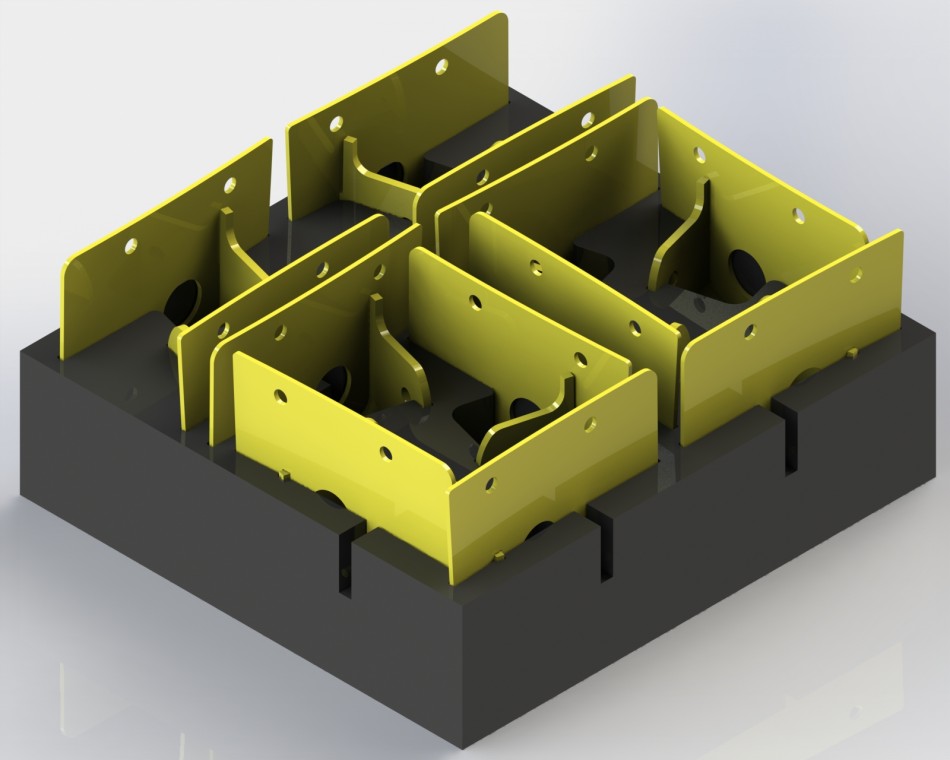

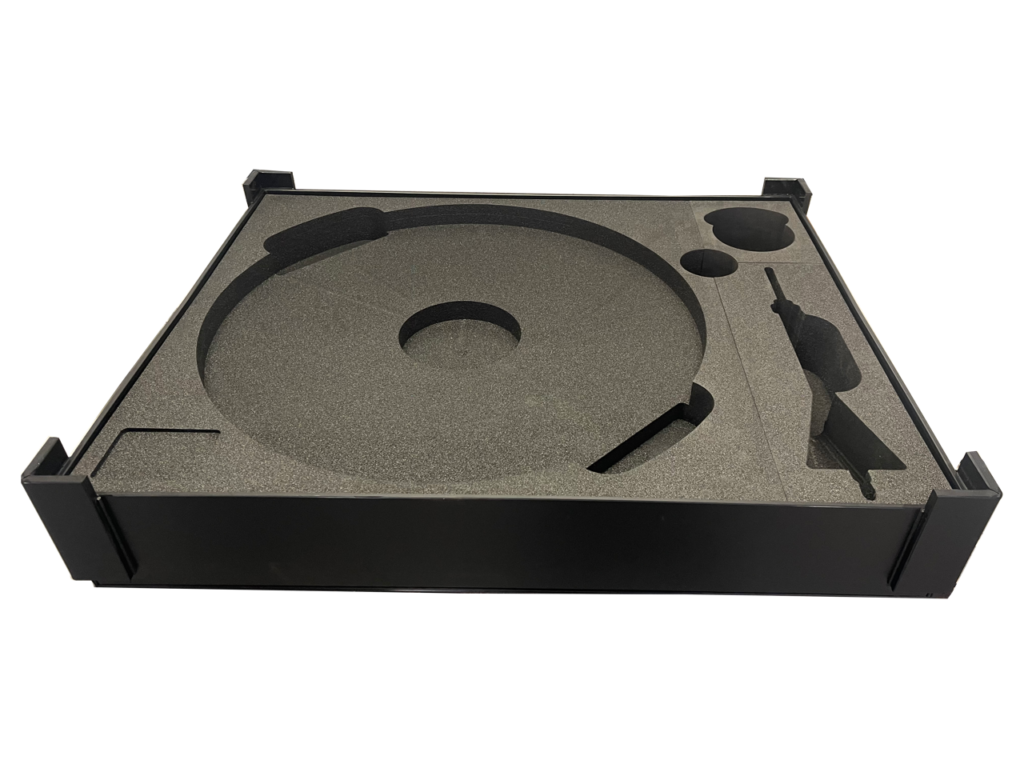

Material Handling Equipment (MHE), which is our specialty at Acres Engineering, includes stillages, trolleys, kanban systems, pick – place solutions, tooling holders etc. Our equipment is designed to move, lift, and handle components, products or equipment, safely and efficiently – easing physical strain on human workers and optimising the movement of goods. This equipment is custom-built to seamlessly integrate with co-bots, creating an advanced, efficient workspace. Our products can range for dolly that can be towed or picked up, to foam inlayed containers allowing robots to pick and place components during processes.

How Co-Bots and Acres Engineering MHE Work Together

The synergy between co-bots and custom MHE can unlock a range of operational benefits, from improved safety to optimised productivity:

- Task Specialisation:

- Co-bots are ideal for handling repetitive, precision-based tasks, such as item picking and placing, while our custom MHE tackles the transport of heavy or bulky loads across the warehouse.

- This division of labor means that co-bots and MHE each handle what they’re best suited for—co-bots manage individual items with accuracy, and MHE, like our lifting and transport systems, streamlines the movement of bulk loads.

- Enhanced Safety and Ergonomics:

- With Acres Engineering’s ergonomic MHE, co-bots can move seamlessly from one task to another without causing strain to human workers. Our equipment handles the heavy lifting and repetitive handling duties, significantly reducing risk of manual handling injuries, and increasing efficiencies.

- This partnership between co-bots and MHE creates a safer working environment, as co-bots handle precision tasks and MHE takes on the strain of weighty loads. It also allows workers to focus on more complex tasks while remaining protected from excessive physical demands.

- Increased Speed and Efficiency:

- Together, co-bots and MHE significantly accelerate order processing and delivery. Co-bots handle individual item sorting, picking, and packing, while custom MHE supports rapid transfer and movement, preventing bottlenecks in warehouse flow.

- By integrating our specialised MHE with co-bots, warehouses can improve the pace and precision of operations, ultimately boosting productivity and reducing delivery times.

- Data-Driven Process Optimisation:

- Both co-bots and MHE at Acres Engineering come equipped with smart technology, which provides real-time data on inventory movements, equipment performance, and workflow optimisation.

- By analysing this data, managers can make informed decisions, route adjustments, and load balancing, ensuring smoother operations that can adjust dynamically to changes in demand.

Real-World Applications of Co-Bots and Acres Engineering MHE

Here’s how our customised MHE integrates seamlessly with co-bots to tackle essential warehouse functions:

- Order Fulfillment: Co-bots swiftly pick items and prepare them for packing, while our custom MHE transports packed items directly to loading docks, reducing manual handling and time spent on transfers.

- Inventory Replenishment: When stock levels are low, our MHE safely moves bulk items to the right shelves, while co-bots ensure each item is stocked precisely where it’s needed.

- Returns Processing: Co-bots handle the inspection and sorting of returned goods, while our ergonomic MHE transports these items to designated storage or refurbishment areas, allowing for an efficient returns process.

Why Choose Acres Engineering’s MHE to Integrate with Co-Bots?

By combining co-bots with custom-designed MHE from Acres Engineering, warehouses experience significant improvements across multiple areas:

- Cost Efficiency: Our equipment reduces labor costs and increases productivity, making warehouses more cost-effective. With co-bots handling specific tasks, warehouses can use their workforce efficiently, reducing downtime and costly errors.

- Worker Morale and Safety: Our ergonomic, MHE solutions create a safer, more enjoyable work environment by reducing the risk of injury and minimising physically demanding tasks.

- Scalability and Agility: As your warehouse needs grow, co-bots and Acres Engineering MHE can scale to meet changing demands. This dynamic system allows you to adapt quickly and efficiently.

Conclusion: Building the Future of Warehouse Collaboration with Acres Engineering

At Acres Engineering, we’re committed to designing and manufacturing MHE that complements the latest in collaborative robotics. Our custom solutions are tailored to meet the specific needs of your manufacturing facility, allowing you to achieve safer, faster, and more efficient operations. By embracing this co-bot and MHE synergy, your facility can stay agile, meet customer demands swiftly, and create an engaging, safe workplace for employees.

Together with Acres Engineering, build a modern, future-ready warehouse that balances automation with human expertise, transforming your workflows and creating a new standard in warehouse efficiency. 🚀

Acres Engineering is the UK’s leading fabricator, specialising in designing innovative solutions that seamlessly integrate with co-bots, robots, and AGVs. Our bespoke material handling equipment and systems optimise automation, enhancing productivity and safety across warehouse and manufacturing environments.

Acres have a range of standard products but also support clients with custom machinery and medium-high volume products such as trolleys, stillages etc.

We have manufactured lots of different tables / workstations / workbenches for various industries.

We also manufacture access platforms, jigs and fixtures and many other types of production support solutions / products.

Talk to us today about your requirements: [email protected] / 01332695240 / Contact Us Form

Click on the icon to check out our social media! Please follow, like and share!

Want to know more about Acres Engineering?

We are based in the UK from our Headquarters in Derbyshire, England and have a European office in Malaga, Spain within the EU.

Find out more about where we have been and what we have been up to by checking out our latest blog posts.

Take a look at how we support of the Armed Forces, STEM/Schools and Charities.

As a world leader in our field, we offer a range of information guides sharing best practice with our clients.

We make it easy to engage with us, we are approved on: EcoVadis (external) / JOSCAR (external) / AVETTA (external) / COUPA (external) / SAP ARIBA (external) / DEEPSTREAM (external) ….you can download our BSI / Insurance certificates here.

![]()

![]()

![]()