What are the benefits of integrating Co-bots with MHE?

Acres Engineering is the UK’s leading fabricator, specialising in designing innovative solutions that seamlessly integrate with co-bots, robots, and AGVs. Our bespoke material handling equipment and systems optimise automation, enhancing productivity and safety across warehouse and manufacturing environments.

What Are the Benefits of Integrating Co-Bots with Manual Production Support Equipment?

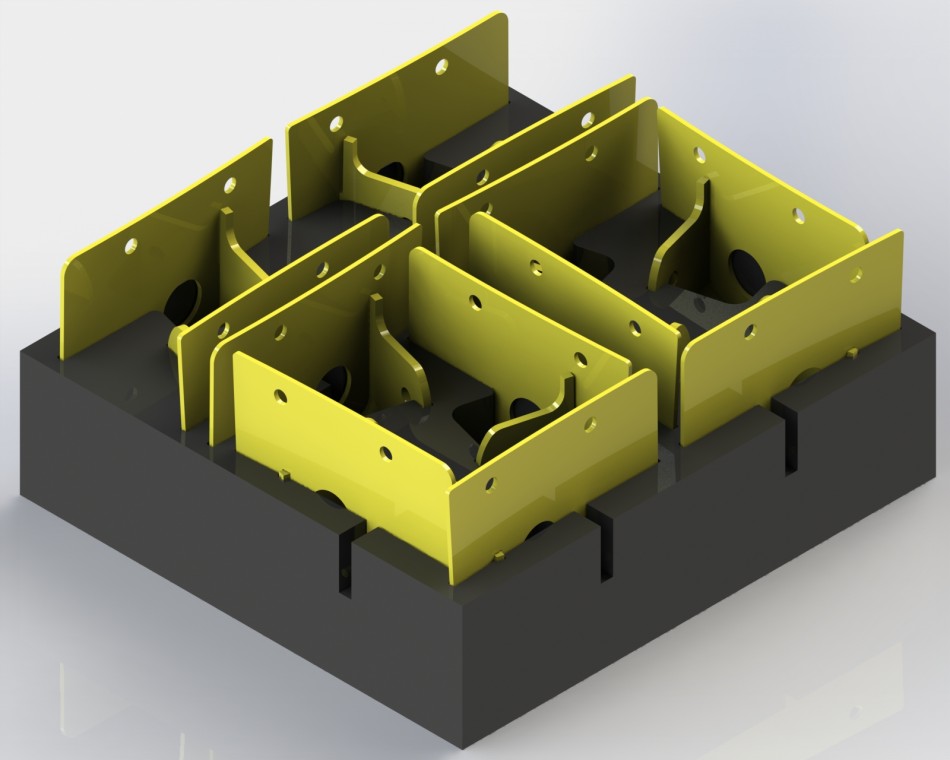

At Acres Engineering, we specialise in designing and manufacturing custom manual production support equipment that’s crafted to integrate seamlessly with collaborative robots (co-bots) in manufacturing and warehouse environments. By combining our production support equipment with advanced co-bots, facilities can achieve a new level of operational efficiency, safety, and flexibility, making production lines more agile and productive than ever before.

Here’s a look at the many benefits of integrating co-bots with Acres Engineering’s bespoke manual production support equipment.

1. Enhanced Productivity and Efficiency

Integrating co-bots with our custom manual production support equipment creates an efficient, balanced workflow that leverages each tool’s unique strengths:

- Streamlined Operations: Co-bots can handle repetitive, precision tasks like picking, placing, or assembling, while our production support equipment, such as lifting aids, trolleys, and ergonomic workstations, supports these tasks by efficiently managing parts, components, and tools.

- Reduced Downtime: With co-bots and our manual support equipment working in harmony, materials and parts are always available where they’re needed. Co-bots signal when they require new parts or when completed items need to be moved, helping prevent production delays and maximising uptime.

2. Improved Workplace Safety

The integration of co-bots and Acres Engineering’s ergonomic manual support equipment helps create a safer working environment by reducing physical strain and minimising risk:

- Ergonomics-First Design: Our equipment is designed to reduce the need for strenuous bending, lifting, or repetitive movements. Co-bots handle the repetitive tasks, while our support equipment positions materials and tools in ergonomically friendly ways, further reducing the risk of strain injuries.

- Minimised Human-Machine Interaction Risks: Co-bots are equipped with safety features that allow them to work safely alongside humans. When integrated with our manual production support equipment, they help streamline workflows without unnecessary human handling, reducing the risk of accidents and fostering a safer work environment.

3. Increased Accuracy and Quality Control

Our production support equipment combined with the precision of co-bots enables enhanced quality control and accuracy in production:

- Consistency in Repetitive Tasks: Co-bots perform precise, repeatable tasks with accuracy, while our equipment ensures that parts, tools, and materials are positioned and handled consistently. This combination enhances product quality, minimises error, and reduces waste.

- Enhanced Inspection Capabilities: Co-bots can perform quality inspections with vision sensors to check for defects, while our production support equipment organises and handles inspected items, ensuring only quality-checked products proceed down the line.

4. Real-Time Data and Operational Insights

Many co-bots, when paired with strategically designed support equipment from Acres Engineering, provide valuable data that can optimise production processes:

- Workflow Optimisation: Co-bots collect data on task performance, speed, and any process issues, which can be combined with information from our support equipment to identify bottlenecks or areas for improvement.

- Predictive Maintenance: Co-bots and data-enabled support equipment can provide alerts for maintenance needs, allowing facility managers to address issues before they lead to downtime. This predictive approach extends the lifespan of equipment and maximises productivity.

5. Cost Savings and Return on Investment (ROI)

Integrating co-bots with Acres Engineering’s production support equipment offers significant cost-saving benefits:

- Labor Efficiency: Co-bots and our equipment take on the repetitive and physically demanding tasks, enabling workers to focus on more complex, high-value roles. This redistribution of labor reduces costs and improves overall productivity.

- Reduced Product Damage and Waste: The precision of co-bots, combined with our ergonomic and stable manual equipment, reduces the risk of product damage. By handling materials carefully, facilities save on the costs associated with damaged goods and waste.

6. Flexibility and Scalability for Changing Demands

Our production support equipment is designed for flexibility, allowing facilities to adapt and scale operations as needed:

- Modular Design: Acres Engineering’s equipment is modular and adjustable, making it easy to reconfigure workstations, add new processes, or adapt to new product lines with minimal disruption. This flexibility is critical in dynamic manufacturing environments.

- Scalable Integration: As production needs change, additional co-bots and Acres Engineering’s production support equipment can be seamlessly added, scaling operations without the need for extensive adjustments to workflows or layout.

7. Enhanced Worker Satisfaction and Engagement

Integrating co-bots with our production support equipment positively impacts worker morale and engagement:

- Reduced Physical Strain: By handling the more strenuous tasks, co-bots and our ergonomic support equipment reduce the physical demands on workers, creating a healthier, safer work environment.

- Improved Job Satisfaction: With repetitive, low-value tasks handled by co-bots and equipment, workers can focus on more meaningful tasks, fostering a sense of contribution and engagement. They gain opportunities to develop new skills and tackle problem-solving tasks, increasing overall job satisfaction.

The Future of Co-Bots and Production Support Equipment Integration

The combination of co-bots with Acres Engineering’s custom-designed manual production support equipment is transforming facilities by creating safe, efficient, and highly adaptable production environments. This integrated approach allows facilities to achieve higher productivity, reduce costs, and foster a safer, more engaging workplace for their employees.

As the industry evolves, this synergy between co-bots and bespoke support equipment will play a central role in shaping agile, responsive manufacturing processes that meet the demands of the future. Embracing this innovation not only keeps facilities competitive but also establishes a foundation for sustainable growth, allowing businesses to create a productive, safe, and forward-looking workspace.

Acres Engineering is the UK’s leading fabricator, specialising in designing innovative solutions that seamlessly integrate with co-bots, robots, and AGVs. Our bespoke material handling equipment and systems optimise automation, enhancing productivity and safety across warehouse and manufacturing environments.

Acres have a range of standard products but also support clients with custom machinery and medium-high volume products such as trolleys, stillages etc.

We have manufactured lots of different tables / workstations / workbenches for various industries.

We also manufacture access platforms, jigs and fixtures and many other types of production support solutions / products.

Talk to us today about your requirements: [email protected] / 01332695240 / Contact Us Form

Click on the icon to check out our social media! Please follow, like and share!

Want to know more about Acres Engineering?

We are based in the UK from our Headquarters in Derbyshire, England and have a European office in Malaga, Spain within the EU.

Find out more about where we have been and what we have been up to by checking out our latest blog posts.

Take a look at how we support of the Armed Forces, STEM/Schools and Charities.

As a world leader in our field, we offer a range of information guides sharing best practice with our clients.

We make it easy to engage with us, we are approved on: EcoVadis (external) / JOSCAR (external) / AVETTA (external) / COUPA (external) / SAP ARIBA (external) / DEEPSTREAM (external) ….you can download our BSI / Insurance certificates here.

![]()

![]()

![]()