Food & Drink Industry

Acres, Solutions Provider to the Food & Drink Industry

You too can benefit from working with Acres, a supplier focussed on value-add and continual improvement. We understand the industry and can help to resolve your challenges freeing you up to concentrate on what you do best…

Key Drivers

Acres’ offering to the food & drink industry aims to make processes safer and efficient whilst reducing footprint and improving quality.

This can be anything from custom machinery to automate tasks or improve quality to simple items such as tray trolleys. We specialise in the design and fabrication of equipment that is used in the food & drink manufacturing process.

-

Quality and handling of produce.

-

Process efficiency, cost down and continual improvement.

-

Ethics and branding.

Expertise

We understand the speed in which the food & drink industry moves and some of the key drivers like safety, efficiency, quality and FOD (foreign object debris) control.

Acres lean engineering experience fits well within the food & drink environment, focusing on value-add and continual improvement. The products Acres deliver are in use across the UK’s leading food & drink manufacturing companies, improving productivity and safety of production processes, enabling them to achieve the best possible outcomes. This is further consolidated on a global basis through networking events and memberships with for example MAKE UK.

-

World Class Product Design.

-

Process Improvement

-

Multi-sector Solutions

Our Food & Drink History

Enter History Title Here.

History ….

-

Re-useable solutions & recyclable materials

-

Contamination reduction

-

CSR engaged supplier

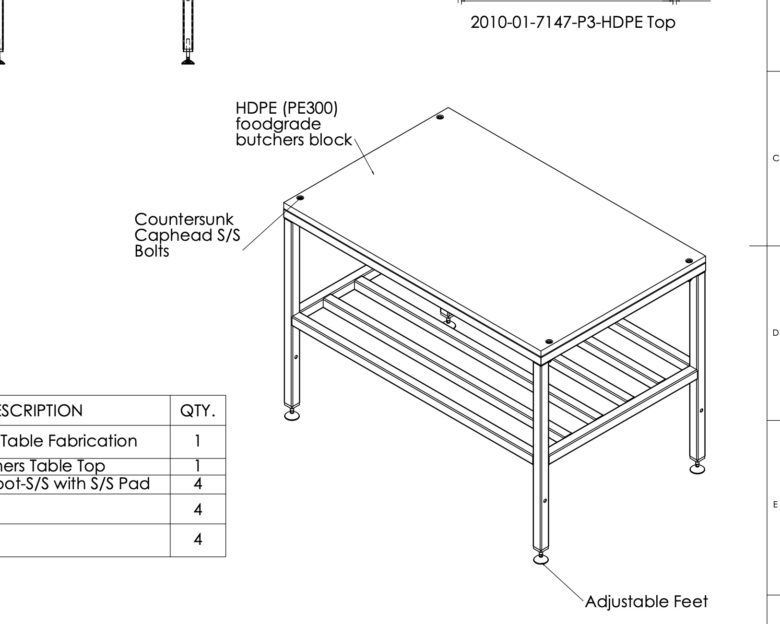

Case Study - Butchery Tables for Fairfax Meadow

Fairfax Meadow wanted to expand and improve its butchery processing area. They wanted to invest in their meat preparation area to ensure they had safe, compliant equipment that facilitated clean down processes to deliver cleanliness excellence. The materials used to manufacture the products reduced the risk of contamination and allowed the area to be thoroughly cleaned after each process.

The butchers block work surface was manufactured from HDPE(PE300) which is a high density polyethylene widely used in food sectors. Polyethylene or P/E is a very popular engineering thermoplastic which is prized for its very low friction and abrasion resistance. It is extremely touch, cost effective and also has very good chemical resistance/ impact strength.

The butchery table was manufactured from 40mm x 40mm x 2mm 304 stainless steel box section, 40mm x 40mm x 3mm 304 stainless steel angle and 40mmx 10mm304 stainless steel flat. The approx size of table was 1250mm (length) x 750mm (width) x 840mm (overall height) and the table is fitted with M12 x 50mm S/S adjustable feet.