JLR plans EV supply chain for UK

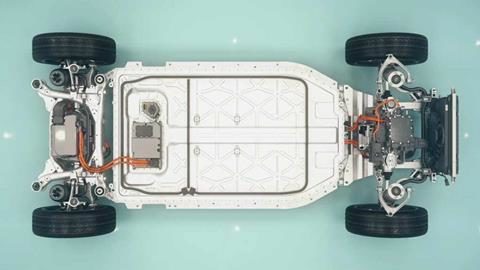

Jaguar Land Rover (JLR) plans to supply electric drives and battery packs from its Wolverhampton Engine Manufacturing Centre to its UK assembly plants for next-generation electric vehicle (EV) production.

The engine plant currently makes the Ingenium internal combustion engine (ICE) but will be renamed the Electric Propulsion Manufacturing Centre and produce electric drives and battery packs to supply EV production at Solihull and Halewood.

The carmaker is investing £15 billion ($18.6 billion) over the next five years to expand and upgrade its UK facilities for EV production. JLR will produce three new EVs at the Solihull plant and develop a medium-size electrified modular architecture for SUV production at Halewood, which will be used to make an all-electric Range Rover from 2025.

“With Range Rover, the original luxury SUV, available for pre-order in pure electric form later this year, and the first of three breath-taking electric reimagined Jaguar models to be launched in 2025, we are stepping into an incredibly exciting new electric era for JLR as a modern luxury business,” said JLR’s CEO, Adrian Mardell.

The company had previously announced that it will be an anchor customer for battery cells from its parent company Tata, which is currently exploring gigafactory locations in either Spain or the UK. Mardell, told journalists that this decision was still pending, but that the plant would not be operational until the middle of the decade. JLR would, in the meantime, source battery cells from other suppliers.

JLR has also confirmed that its Castle Bromwich plant, which currently builds Jaguar vehicles but whose future has been unclear beyond 2025, will expand its stamping facilities for pressed body metalwork for the next generation of EVs. JLR has yet to confirm what other operations will be at the plant but has said that it continues to explore options for other parts of Castle Bromwich.

JLR reported increased sales in the first quarter of 2023 to more than 94,600 vehicles, up 24% compared to the same period last year, which it said reflected a continuation of the gradual improvement in chip and other supply constraints.