Starrag supply Australia with their largest machine tool ‘ever

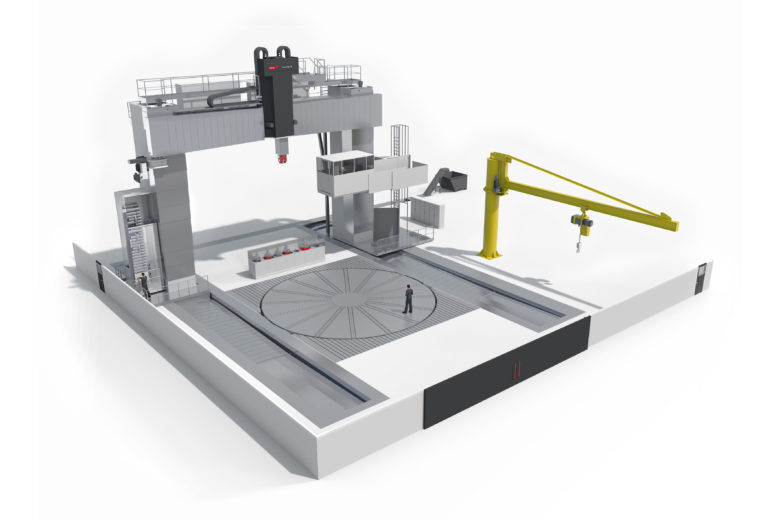

A Starrag group has supplied Australia with a Droop+Rain five-axis gantry milling machine, the largest machine ever to be put into operation there.

Starrag Group is a global technology leader in manufacturing high-precision machine tools for milling, turning, boring and grinding workpieces of metallic, composite and ceramic materials, and offers a wide range of machining technologies from horizontal machining centres to aerostructure machines.

The Milling machine, which includes an X, Y and Z-axis traverses of 14,000 mm x 13,000 mm, 3,500, was supplied to the Naval Group in Osborne, Australia. The five-axis giant, which also includes an 11-metre rotary table to permit long operations in the same setup, will be used to machine hull elements and high-precision components for the Royal Australian Navy’s Attack class submarines.

The contract was awarded following a complex selection process. Noting its many years of experience and its extensive expertise in handling large, complicated projects, the Starrag Group was an obvious selection for the contract.

The order for the machine comes after the Australian Government (Commonwealth of Australia) selected French company Naval Group to deliver a fleet of 12 regionally superior submarines, to be built in a modern construction yard in Osborne, South Australia.

The Future Submarine Program will deliver Australia a capability that can be built, operated and maintained with sovereignty, which maximises opportunities for Australian industry throughout all phases of the programme.

As the design of the Attack class progresses, the Naval Group continues to deliver on its commitment to achieving this through its suppliers – a pool that now includes the Starrag Group which has been selected to supply a Droop+Rein G 110TT HR100 C vertical gantry machine, capable of handling both large hull elements and high-precision components for submarine construction.

Source: Made in the Midlands