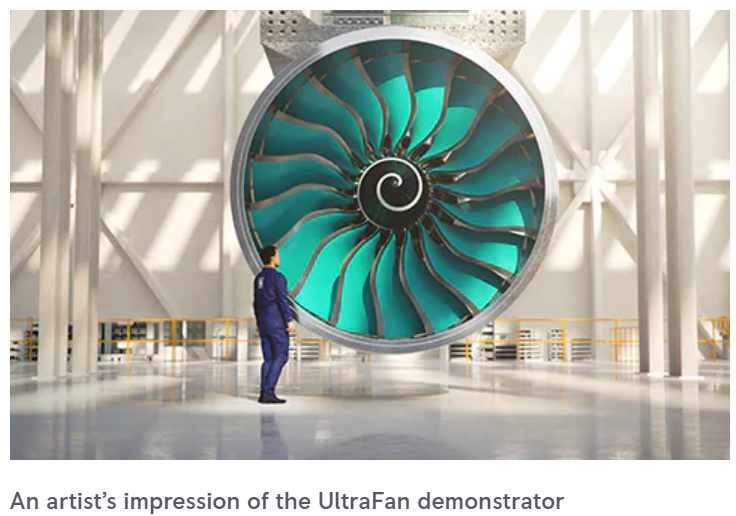

Work starts on building first UltraFan aero engine

Rolls-Royce has started work on building UltraFan, an aero engine with a 140” fan diameter that is expected to ‘redefine sustainable air travel’.Work is underway on the world’s largest aero-engine at the company’s DemoWorks facility in Derby and the demonstrator engine will be completed by the end of the year. The first test run of the engine will be conducted on 100 per cent Sustainable Aviation Fuel (SAF).The engine is the basis for a potential new family of UltraFan engines for narrow and widebody aircraft and will deliver a 25 per cent fuel efficiency improvement compared with first-generation Trent engines. According to Rolls-Royce, gas turbines will continue to power long-haul aviation for many years and UltraFan is expected to help the transition to more sustainable fuels, which are likely to be more expensive in the short-term than traditional jet fuel.

Sources of funding for the UltraFan demonstrator and associated technologies include the Aerospace Technology Institute and Innovate UK, LuFo (Germany) and the EU’s Clean Sky Joint Undertaking.

In a statement, Chris Cholerton, Rolls-Royce, President – Civil Aerospace, said: “This is an exciting moment for all of us at Rolls-Royce. Our first engine demonstrator, UF001, is now coming together and I’m really looking forward to seeing it built and ready for test. It is arriving at a time when the world is seeking ever more sustainable ways to travel in a post-COVID 19 world, and it makes me and all our team very proud to know we are part of the solution.”

As engine build starts, other key parts are already coming together for delivery to Derby. Work is underway on UltraFan’s carbon titanium fan system in Bristol, and its 50MW Power Gearbox in Dahlewitz, Germany.

Features of the engine include Advance 3 core architecture combined with Rolls-Royce’s ALECSys lean burn combustion system, to deliver maximum fuel burn efficiency and low emissions, carbon titanium fan blades and a composite casing that reduces weight by up to 1,500lb per aircraft, advanced ceramic matrix composite (CMC) components that operate more effectively in high pressure turbine temperatures, and a geared design that delivers efficient power for the high-thrust, high bypass ratio engines of the future.

Source: The Engineer