Assembly Jig

Assembly Jig

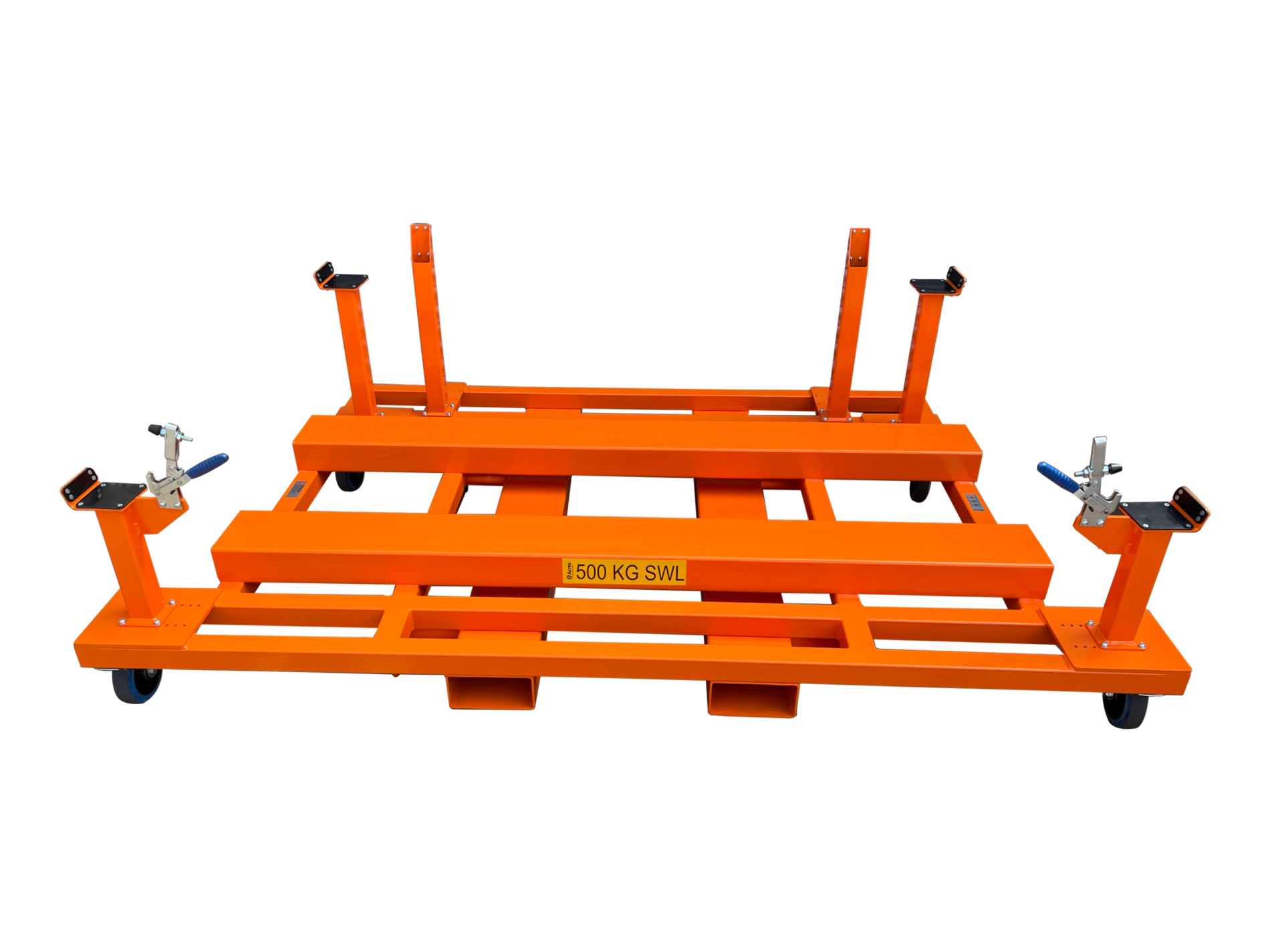

Scope We designed and manufactured an assembly jig to optimise the assembly process by ensuring precise alignment and consistent positioning of components. The jig allows for faster, more accurate assembly, reducing the potential for errors and minimising variations between units.…

Read More

Scope

We designed and manufactured an assembly jig to optimise the assembly process by ensuring precise alignment and consistent positioning of components. The jig allows for faster, more accurate assembly, reducing the potential for errors and minimising variations between units. By creating a custom solution tailored to your specific needs, we can improve the overall efficiency of production, reduce assembly time, and maintain high-quality standards across each product. This approach not only streamlines your manufacturing process but also helps in reducing costs, increasing throughput, and ensuring the final product meets your exact specifications.

Solution

Project REF: AD-2321-2023-07-2 / 12654-P1

A jig is a specialised tool or device used in manufacturing and assembly processes to guide, support, or hold a workpiece in place during operations like cutting, drilling, welding, or assembly. Its main purpose is to ensure accuracy, consistency, and repeatability by providing a stable and fixed position for the parts being worked on. Jigs are typically custom-designed for specific tasks, helping to reduce errors, speed up production, and improve the overall quality of the product.

For example, in assembly, a jig might be used to position components in the correct orientation before they are fastened together, ensuring all parts align correctly each time.

Jigs offer several key benefits in manufacturing and assembly processes, including:

-

Increased Accuracy and Precision: Jigs ensure that parts are consistently positioned in the same way every time, reducing the chances of human error and ensuring high precision in measurements, cuts, or assembly steps.

-

Improved Efficiency: By providing a fixed and repeatable setup, jigs reduce setup time and help workers perform tasks faster. This leads to faster production times and better overall throughput.

-

Consistency and Repeatability: With a jig, the same steps can be repeated accurately on multiple units, ensuring that each product is identical and meets the same quality standards.

-

Reduced Labor Costs: As jigs minimise errors and improve speed, they reduce the need for rework or corrections. This lowers the amount of labor time required, ultimately saving costs.

-

Enhanced Quality Control: Since jigs provide precise alignment and positioning, they help ensure that products meet high-quality standards and specifications, leading to fewer defects and returns.

-

Reduced Risk of Damage: Jigs help hold parts securely in place, reducing the chance of damage to delicate components during processing or assembly.

-

Flexibility for Complex Parts: Custom jigs can be designed to handle complex or irregularly shaped parts, providing solutions for manufacturing that would be difficult or inefficient with standard tools.

-

Safety: By stabilising the workpiece, jigs help reduce the risk of accidents or injury during manufacturing processes, especially in operations involving heavy machinery or tools.

Overall, jigs are valuable tools for improving the quality, speed, and consistency of manufacturing and assembly processes, benefiting both production efficiency and product reliability.

Jigs are highly versatile tools used in various manufacturing and assembly tasks to ensure precision, consistency, and efficiency. They can be used for drilling, machining, assembly, welding, cutting, shaping, soldering, inspection, and testing. Jigs are also applied in industries like automotive, aerospace, electronics, woodworking, and textiles, assisting in tasks such as aligning parts, holding materials in place, guiding tools, and improving product quality. Their adaptability makes them valuable for numerous processes, from simple assembly to complex operations across different industries.

An assembly jig can be used in a variety of industries where precision, efficiency, and consistency are critical during the manufacturing or assembly process. Some key industries include:

-

Automotive Industry: In automotive manufacturing, jigs are used to assemble various parts of vehicles, such as engine components, chassis, and interior assemblies. They ensure parts align correctly and are assembled efficiently.

-

Aerospace Industry: Assembly jigs are crucial in the aerospace sector, where they help assemble complex components like aircraft frames, wings, and engine parts. Precision and repeatability are vital due to strict safety and performance standards.

-

Electronics Manufacturing: Jigs are used in the assembly of electronic devices, such as circuit boards, smartphones, and other gadgets. They assist in positioning delicate components accurately for soldering or testing.

-

Construction and Heavy Machinery: Assembly jigs are used in the construction and heavy equipment industries to assemble large components like machinery frames, engines, and structural parts, ensuring proper alignment and minimising errors during assembly.

-

Shipbuilding: Jigs are used in shipbuilding for the assembly of large, complex parts like hulls, engine rooms, and navigation systems, helping to position and align parts for welding and installation.

-

Defence and Military: Similar to aerospace, the defense industry uses jigs for assembling complex weaponry, vehicles, and systems with high precision, ensuring reliability and performance.

-

Furniture Manufacturing: In furniture production, jigs help position and assemble components like frames, joints, and hardware, ensuring uniformity and faster assembly.

In essence, any industry that requires repetitive, precise assembly of parts or components can benefit from the use of an assembly jig.

Acres have a range of standard products but also support clients with custom machinery and medium-high volume products such as trolleys, stillages etc.

We have manufactured lots of different tables / workstations / workbenches for various industries.

We also manufacture access platforms, jigs and fixtures and many other types of production support solutions / products.

Talk to us today about your requirements: [email protected] / 01332695240 / Contact Us Form

Click on the icon to check out our social media! Please follow, like and share!

Want to know more about Acres Engineering?

We are based in the UK from our Headquarters in Derbyshire, England and have a European office in Malaga, Spain within the EU.

Find out more about where we have been and what we have been up to by checking out our latest blog posts.

Take a look at how we support of the Armed Forces, STEM/Schools and Charities.

As a world leader in our field, we offer a range of information guides sharing best practice with our clients.

We make it easy to engage with us, we are approved on: EcoVadis (external) / JOSCAR (external) / AVETTA (external) / COUPA (external) / SAP ARIBA (external) / DEEPSTREAM (external) ….you can download our BSI / Insurance certificates here.

![]()

![]()

![]()

Have a design and development project you want the Acres team to look at? Can’t see what you want? Need something different?

Acres Engineering is established as a leader in delivering bespoke creative engineered solutions. Many OEM’s and tier one/ two suppliers in aerospace, automotive, rail and power generation industries have chosen us as their solutions partner because of our innovative attitude towards individual challenges and commitment to continual improvement.