Coupling Assembly Enerpac Trolley

Coupling Assembly Enerpac Trolley

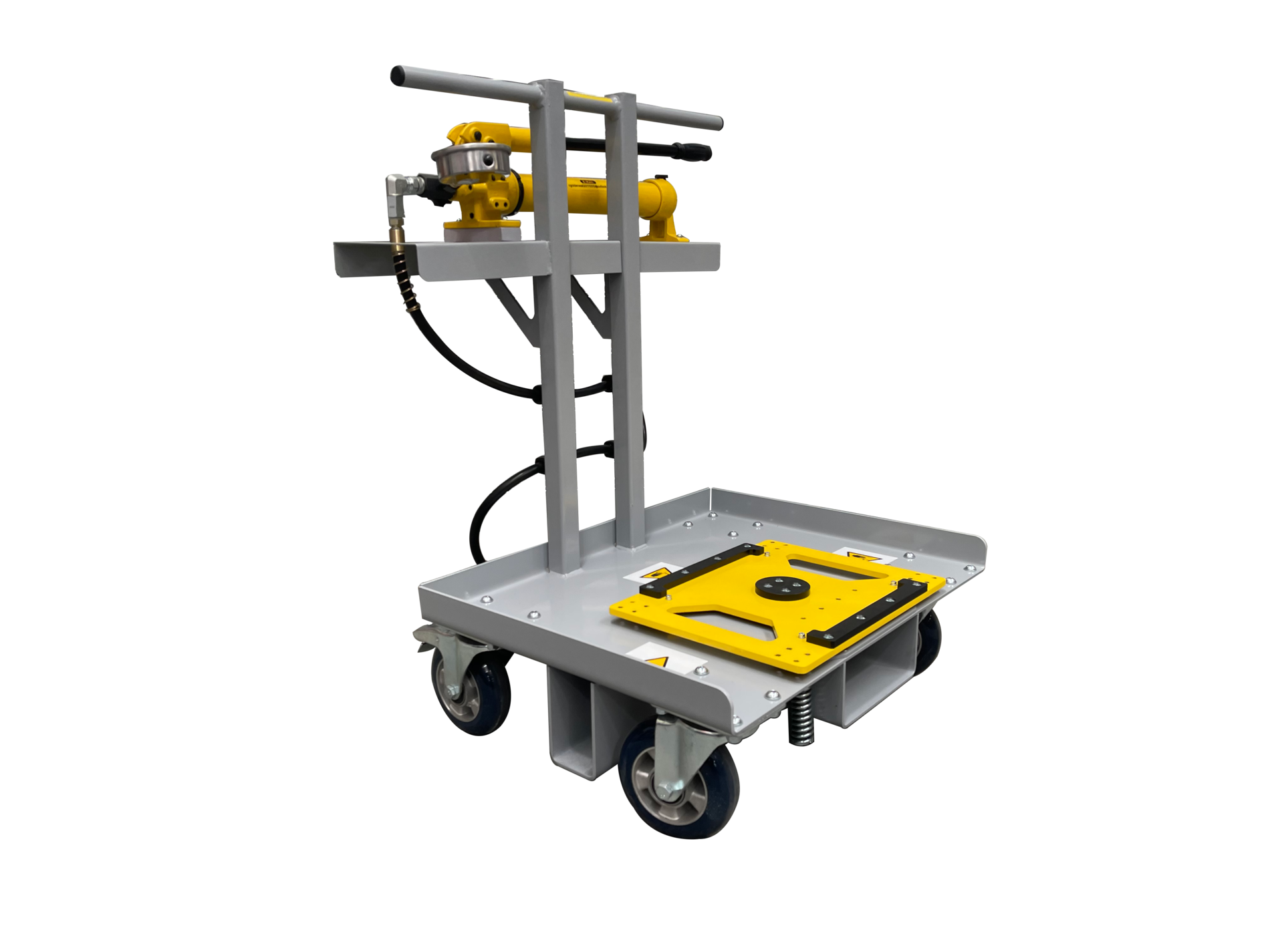

Scope To design and manufacture a trolleys to safely transport and lift couplings into position using a hydraulic pump system. Solution Project REF: AD-2471-2024-03-1 / 12503-P1 Coupling trolleys are specialised tools used in railway and industrial settings for managing…

Read More

Scope

To design and manufacture a trolleys to safely transport and lift couplings into position using a hydraulic pump system.

Solution

Project REF: AD-2471-2024-03-1 / 12503-P1

Coupling trolleys are specialised tools used in railway and industrial settings for managing coupling systems. They serve several key purposes:

- Facilitating Coupling Operations: Provide a stable platform for easy connection and disconnection of heavy equipment.

- Enhancing Safety: Minimise risks of accidents by allowing safe manipulation of heavy coupling components.

- Improving Efficiency: Feature storage for tools, reducing downtime and speeding up maintenance tasks.

- Providing Mobility: Equipped with wheels for easy movement around workshops and rail yards, enhancing operational flexibility.

- Supporting Various Coupling Types: Compatible with different couplers, making them versatile for various applications.

- Maintenance and Inspection: Allow easy access for regular maintenance and repairs, ensuring reliability.

- Lifting Heavy Loads: Often include hydraulic systems to reduce physical strain on workers.

A coupling is a mechanical device used to connect two shafts or pieces of equipment, allowing them to transmit power, torque, or motion from one to the other. Couplings are essential in various applications, particularly in machinery, automotive systems, and railway systems. A hydraulic pump system is therefore used on a coupling assembly trolley to provide an essential component that facilitates the movement and handling of heavy coupling parts and assemblies. This system utilises hydraulic power to enable easier operation, improve efficiency, and enhance safety when dealing with substantial loads.

Coupling trolleys, while primarily used in railway and industrial settings for managing coupling systems, have diverse applications across various sectors:

- Heavy Machinery Maintenance: Assist in assembling and disassembling components like motors and gearboxes.

- Transporting Heavy Loads: Facilitate the movement of heavy equipment within factories, warehouses, and construction sites.

- Construction Applications: Help move large components, improving workflow and safety on job sites.

- Automotive Repair and Maintenance: Aid in maintaining vehicle coupling systems, enhancing repair efficiency.

- Railcar Modifications: Facilitate upgrades or modifications to railcars, including new coupling installations.

- Testing and Inspection: Used in testing environments to simulate coupling connections and evaluate performance.

- Educational and Training Purposes: Provide hands-on experience for training technicians and engineers on coupling systems.

- R&D and Prototyping: Utilised in labs for prototyping new coupling designs and safely testing components.

The concept of a Safe Working Load (SWL) is critical in the context of coupling trolleys and other lifting equipment. SWL refers to the maximum load that a piece of equipment is designed to safely handle under specific conditions without risking failure or accidents. Here are several reasons why the SWL is important for coupling trolleys:

1. Safety Assurance

- Preventing Accidents: Adhering to the SWL helps prevent overloading, which can lead to equipment failure, accidents, and injuries. This is crucial in environments where heavy lifting and moving of coupling components are common.

2. Equipment Integrity

- Avoiding Damage: Exceeding the SWL can cause structural damage to the trolley, including bending, breaking, or deforming components. Ensuring that loads remain within the specified limits helps maintain the trolley’s functionality and lifespan.

3. Compliance with Regulations

- Legal Standards: Many industries are subject to safety regulations and standards that specify maximum load limits for lifting equipment. Complying with these regulations helps organisations avoid legal liabilities and fines.

4. Operational Efficiency

- Minimising Downtime: Regularly operating within the SWL ensures that the trolley functions optimally, reducing the likelihood of breakdowns and the associated downtime for repairs or replacements.

5. Risk Management

- Mitigating Liability: In the event of an accident involving overloading, the organisation may face liability claims or insurance issues. Following SWL guidelines helps mitigate these risks and enhances overall workplace safety.

6. Improved Workflow

- Confidence in Equipment: Knowing that the trolley is used within its SWL allows operators to work with confidence, leading to more efficient workflow and productivity as workers are less likely to be concerned about potential equipment failures.

7. Training and Awareness

- Promoting Best Practices: Understanding and respecting SWL contributes to a culture of safety among workers. Training employees about the importance of adhering to load limits fosters awareness and encourages safe practices in the workplace.

8. Enhancing Collaboration

- Team Safety: In environments where multiple workers handle heavy loads, knowing the SWL of equipment promotes safer teamwork and communication, ensuring everyone is aware of the limits and operational protocols.

Take a look at our information page all about safe working loads:

Acres have a range of standard products but also support clients with custom machinery and medium-high volume products such as trolleys, stillages etc.

We have manufactured lots of different tables / workstations / workbenches for various industries.

We also manufacture access platforms, jigs and fixtures and many other types of production support solutions / products.

Talk to us today about your requirements: [email protected] / 01332695240 / Contact Us Form

Click on the icon to check out our social media! Please follow, like and share!

Want to know more about Acres Engineering?

We are based in the UK from our Headquarters in Derbyshire, England and have a European office in Malaga, Spain within the EU.

Find out more about where we have been and what we have been up to by checking out our latest blog posts.

Take a look at how we support of the Armed Forces, STEM/Schools and Charities.

As a world leader in our field, we offer a range of information guides sharing best practice with our clients.

We make it easy to engage with us, we are approved on: EcoVadis (external) / JOSCAR (external) / AVETTA (external) / COUPA (external) / SAP ARIBA (external) / DEEPSTREAM (external) ….you can download our BSI / Insurance certificates here.

![]()

![]()

![]()

Have a design and development project you want the Acres team to look at? Can’t see what you want? Need something different?

Acres Engineering is established as a leader in delivering bespoke creative engineered solutions. Many OEM’s and tier one/ two suppliers in aerospace, automotive, rail and power generation industries have chosen us as their solutions partner because of our innovative attitude towards individual challenges and commitment to continual improvement.