Deck Stillage

Deck Stillage

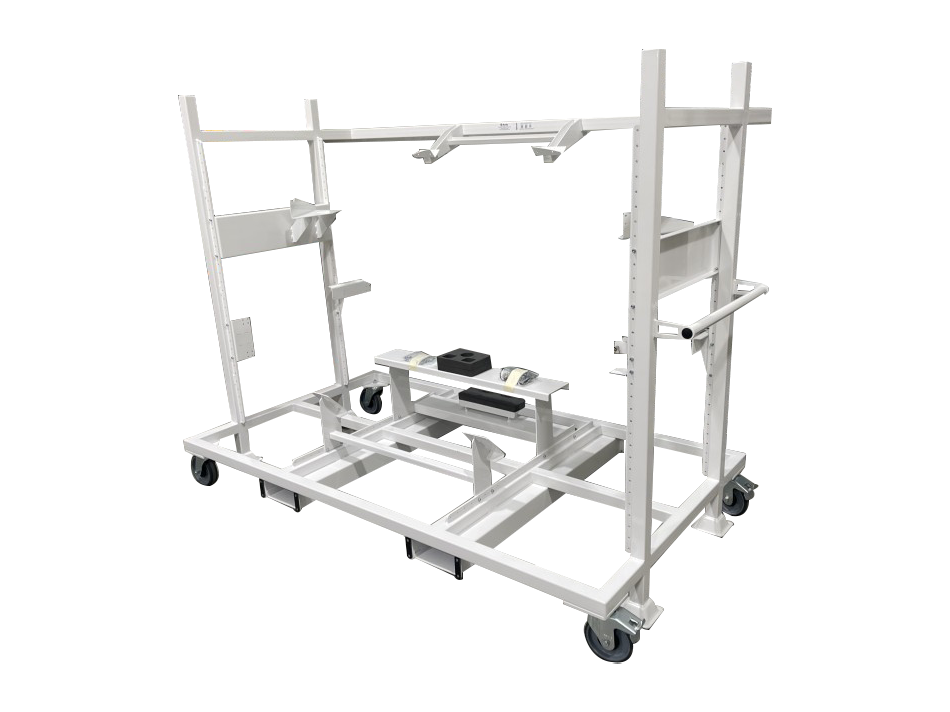

Scope We manufactured a rear deck stillage for our customer based on their supplied drawing to ensure a tailored solution that meets their specific handling and transport requirements. By working from their initial concept design, we were able to produce…

Read More

Scope

We manufactured a rear deck stillage for our customer based on their supplied drawing to ensure a tailored solution that meets their specific handling and transport requirements. By working from their initial concept design, we were able to produce a stillage that accurately accommodates the rear deck components, ensuring secure storage, safe movement throughout their production process, and efficient loading during transportation. This approach also ensured full compatibility with their internal logistics systems and helped maintain the integrity of the parts throughout the supply chain.

Solution

Project REF: AD-2490-2024-04-1 / 12706-P1

A deck stillage is a purpose-built metal frame or cage, specifically designed to facilitate the safe, organised, and damage-free handling, storage, and transportation of rear deck components. These stillages are custom-engineered to match the precise dimensions, weight, and geometry of the parts they are intended to carry—typically rear deck panels or trims used in automotive manufacturing.

By providing structured support and compartmentalisation, the deck stillage ensures that each component is held securely in place, preventing movement, scratching, deformation, or impact damage during handling, storage, and transit. This not only protects the integrity and quality of the parts but also significantly reduces waste and rework due to transport-related defects.

Why are deck stillages crucial to the automotive sector?

-

Protection of Rear Deck Components

- Deck stillages are purpose-built to securely hold parts, reducing the risk of scratches, dents, or deformation during storage and transportation. This ensures components arrive at the production line in optimal condition, minimising quality issues and rework.

-

Safe and Damage-Free Handling

- The structured design of stillages supports safe movement of parts across multiple handling stages—internally and externally—preventing damage that could compromise product integrity.

-

Support for Lean Manufacturing Principles

- Stillages streamline part flow by reducing manual handling, organising components more efficiently, and helping eliminate unnecessary movement or delays on the shop floor.

-

Improved Loading and Unloading Efficiency

- Their ergonomic and organised layout allows faster, more efficient loading and unloading of parts, reducing cycle times and increasing productivity.

-

Space Optimisation and Stackability

- Designed to maximise available floor and transport space, stillages can be safely stacked, helping reduce storage footprint and transport costs.

-

Compatibility with Handling Equipment

- Stillages are designed to integrate seamlessly with standard handling equipment (e.g., forklifts, cranes, automated systems), ensuring smooth operations in both manual and automated environments.

-

Reusability and Durability

- Built for long-term use, deck stillages eliminate the need for disposable packaging, resulting in lower material waste and improved cost efficiency over time.

-

Sustainability and Waste Reduction

- The use of reusable stillages reduces reliance on single-use materials like cardboard or plastic, supporting the company’s environmental goals and reducing overall carbon footprint.

Other Sectors Where Deck Stillages Can Be Used:

- Aerospace: For safe transport of aircraft panels and assemblies.

- Rail Industry: Ideal for train interior panels and structural components.

- Heavy Engineering: Suitable for fabricated metal parts and structural assemblies.

- Glass & Glazing Industry: Protects fragile glass panels and window frames.

- Renewable Energy: Transport of solar panel frames and wind turbine components.

- Agricultural Equipment Manufacturing: For large machinery panels and parts.

- Marine Industry: Handles boat deck panels and fiberglass components.

Acres have a range of standard products but also support clients with custom machinery and medium-high volume products such as trolleys, stillages etc.

We have manufactured lots of different tables / workstations / workbenches for various industries.

We also manufacture access platforms, jigs and fixtures and many other types of production support solutions / products.

Talk to us today about your requirements: [email protected] / 01332695240 / Contact Us Form

Click on the icon to check out our social media! Please follow, like and share!

Want to know more about Acres Engineering?

We are based in the UK from our Headquarters in Derbyshire, England and have a European office in Malaga, Spain within the EU.

Find out more about where we have been and what we have been up to by checking out our latest blog posts.

Take a look at how we support of the Armed Forces, STEM/Schools and Charities.

As a world leader in our field, we offer a range of information guides sharing best practice with our clients.

We make it easy to engage with us, we are approved on: EcoVadis (external) / JOSCAR (external) / AVETTA (external) / COUPA (external) / SAP ARIBA (external) / DEEPSTREAM (external) ….you can download our BSI / Insurance certificates here.

![]()

![]()

![]()

Have a design and development project you want the Acres team to look at? Can’t see what you want? Need something different?

Acres Engineering is established as a leader in delivering bespoke creative engineered solutions. Many OEM’s and tier one/ two suppliers in aerospace, automotive, rail and power generation industries have chosen us as their solutions partner because of our innovative attitude towards individual challenges and commitment to continual improvement.