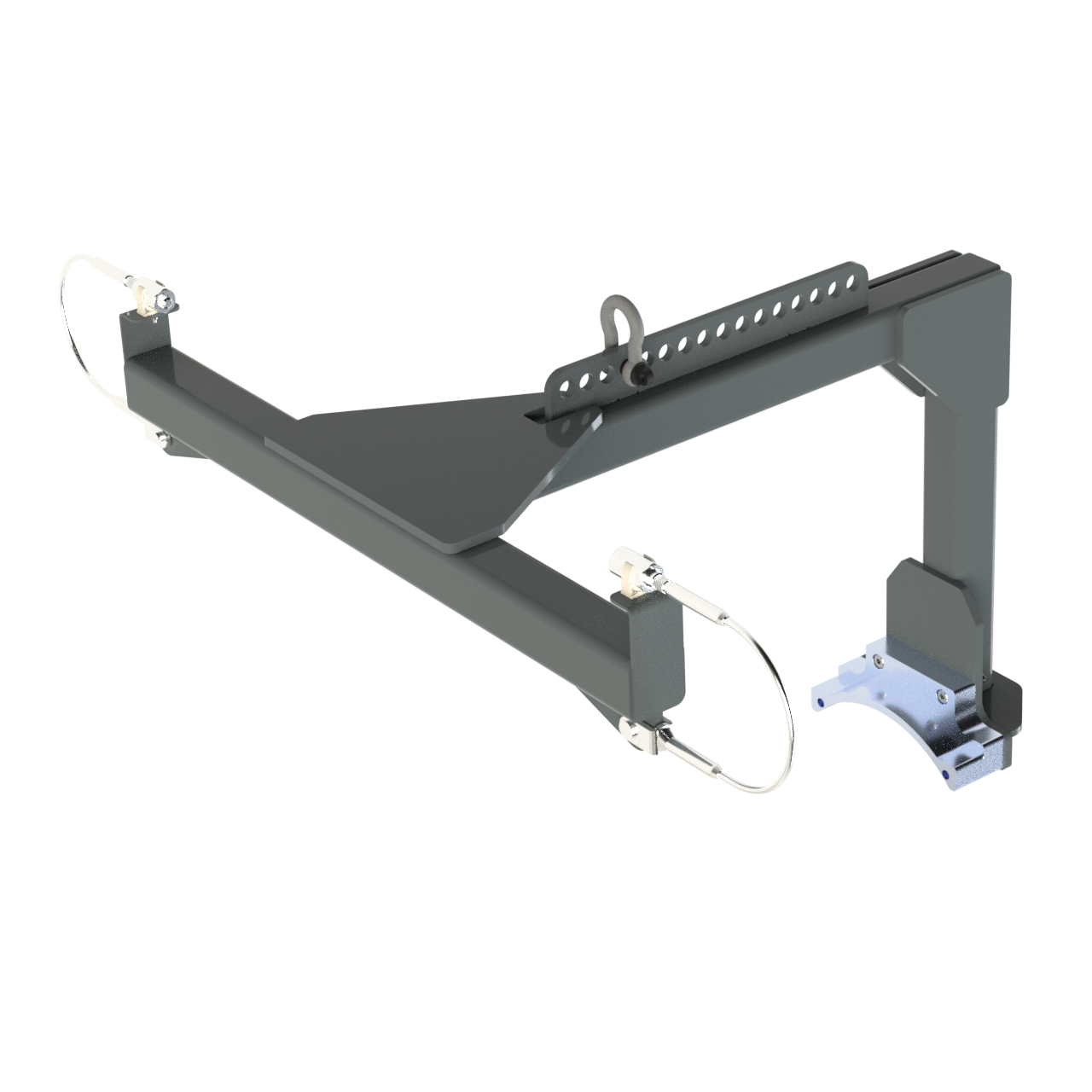

Engine lifting arm

Engine lifting arm

Scope Our customer asked us to manufacture an Engine Lifting Arm in line with their supplied specifications. The arm will be used for offloading the engine from a stillage and loading it onto the engine table. – Mounts off the…

Read More

Our customer asked us to manufacture an Engine Lifting Arm in line with their supplied specifications.

Scope

Our customer asked us to manufacture an Engine Lifting Arm in line with their supplied specifications.

The arm will be used for offloading the engine from a stillage and loading it onto the engine table.

– Mounts off the 4 crankcase studs.

– Fitted with Adjustable Cables

– Machined engine interface block to safely locate on the engine.

– Lifting capacity 500kg.

– Clearance to all engine components.

– Compatible with various specific study engines.

Powder Coated Grey RAL 7012

Solution

Project REF: AD-2715-2024-11-2 / 13271-P1

Key Benefits of a Custom Engine Lifting Arm

1. Optimised Fit and Performance

Designed specifically for the manufacturer’s engine models, ensuring precise and balanced lifting with minimal risk to components.

2. Enhanced Safety

Built-in ergonomic and fail-safe features reduce operator risk and ensure safe engine handling during movement, installation and removal.

3. Increased Efficiency

Streamlines workflows by speeding up lifting operations and integrating seamlessly with existing tooling or automation systems.

4. Reduced Damage Risk

Protects sensitive engine parts by minimizing unnecessary contact, with consistent, repeatable handling.

5. Space and Workflow Integration

Customizable to fit the plant layout and existing crane or workstation systems, saving space and improving workflow.

6. Long-Term Cost Savings

Durable materials and lower maintenance needs contribute to reduced total cost of ownership over time.

7. Compliance and Branding

Can be engineered to meet safety standards and include branding, digital links, or integration with smart factory systems.

—————————————————————

Acres have a range of standard products but also support clients with custom machinery and medium-high volume products such as trolleys, stillages etc.

We have manufactured lots of different tables / workstations / workbenches for various industries.

We also manufacture access platforms, jigs and fixtures and many other types of production support solutions / products.

Talk to us today about your requirements: [email protected] / 01332695240 / Contact Us Form

Click on the icon to check out our social media! Please follow, like and share!

Want to know more about Acres Engineering?

We are based in the UK from our Headquarters in Derbyshire, England and have a European office in Malaga, Spain within the EU.

Find out more about where we have been and what we have been up to by checking out our latest blog posts.

Take a look at how we support of the Armed Forces, STEM/Schools and Charities.

As a world leader in our field, we offer a range of information guides sharing best practice with our clients.

We make it easy to engage with us, we are approved on: EcoVadis (external) / JOSCAR (external) / AVETTA (external) / COUPA (external) / SAP ARIBA (external) / DEEPSTREAM (external) ….you can download our BSI / Insurance certificates here.

![]()

![]()

![]()

Have a design and development project you want the Acres team to look at? Can’t see what you want? Need something different?

Acres Engineering is established as a leader in delivering bespoke creative engineered solutions. Many OEM’s and tier one/ two suppliers in aerospace, automotive, rail and power generation industries have chosen us as their solutions partner because of our innovative attitude towards individual challenges and commitment to continual improvement.