Trak® Xchange Battery Changer – PU 1250-1000 Dual Height

Trak® Xchange Battery Changer – PU 1250-1000 Dual Height

Fork Truck Battery Changer – PU 1250-1000 Dual Height: As part of an ongoing relationship with Hoppecke Batterien, Acres regularly produce a number of bespoke fork truck battery changer units to suit customer requirements. Our product has improved incrementally over the…

Read More

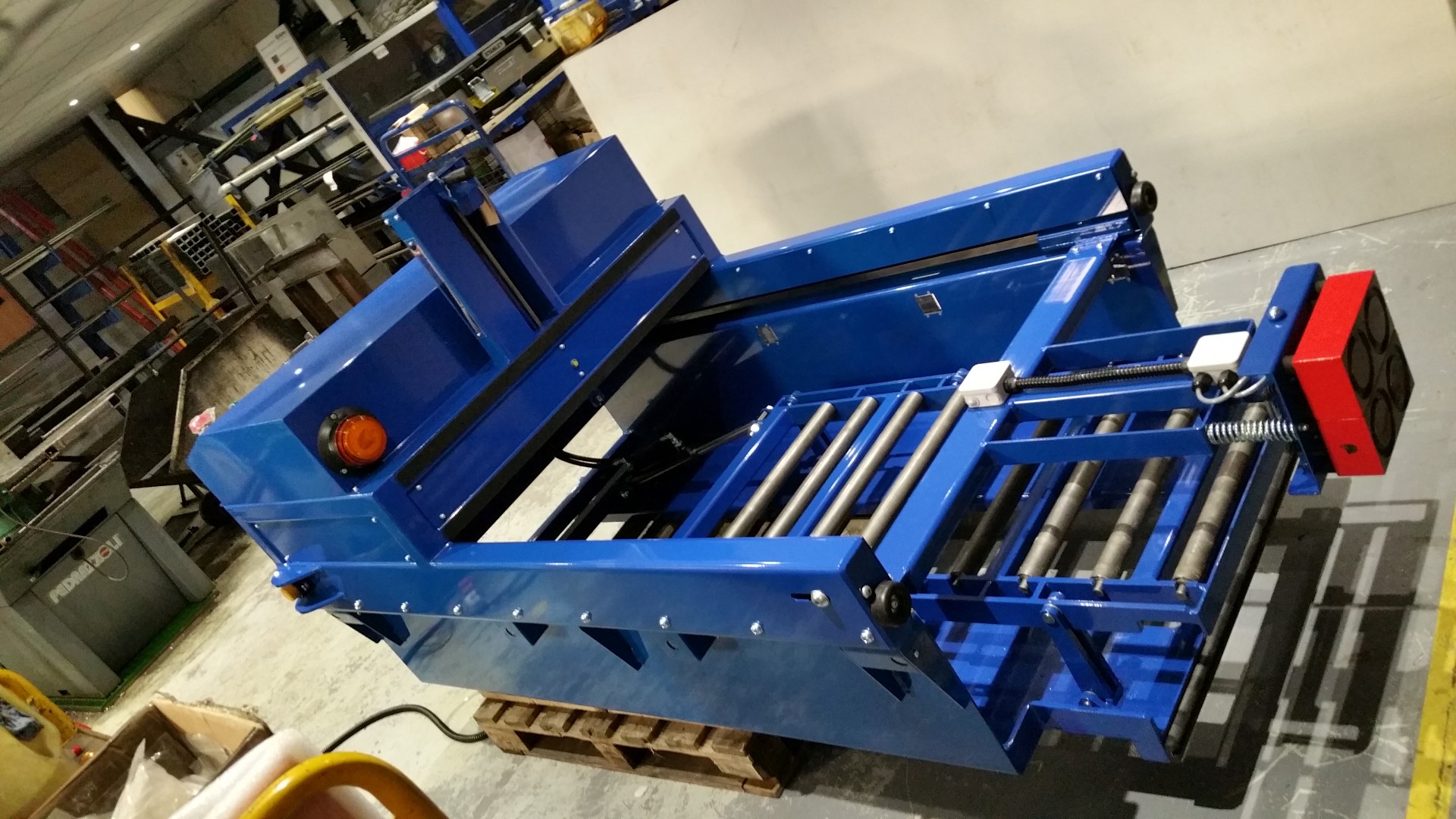

Fork Truck Battery Changer – PU 1250-1000 Dual Height:

As part of an ongoing relationship with Hoppecke Batterien, Acres regularly produce a number of bespoke fork truck battery changer units to suit customer requirements. Our product has improved incrementally over the years giving our designers and fabricators a wealth of experience to tackle almost any request.

The Acres PU machine is fixed to a PPT (Powered Pallet Truck) providing a fast and efficient mobile battery changing solution for around the clock warehouse operations. The PU is powered by a hydraulic power pack which, in partnership with a pair of powerful magnets exchanges batteries between fork trucks and battery charging racks.

Acres are currently exporting custom machines to Germany, France, Belgium, Spain, Poland, Holland, Slovakia, Abu Dhabi, Dubai, South Africa and China as well as serving the UK.

For more information about the Hoppecke battery changing unit see: The trak® Xchange PU.

Design Scope:

This bespoke design features a dual height bed with extended magnet head to remove a multitude of batteries at a range of roll off heights as well as reach inset batteries otherwise obscured within the fork-truck chassis. This design also features a proxy sensor to detect the magnet safe zone and enable/disable the PPT’s movement ensuring full user safety. In addition a laser guide have been incorporated to assist the operator with levelling the bed and speed up the exchange process.

Destination:

Hoppecke France

Machine Specification:

Roll off heights: 150mm to 430mm

Height minimum 150 mm

Height maximum 430mm

+ 160mm raise in roller bed

Magnet extension of 500mm

Roller bed extension/ protrusion of 200mm

Extended chassis frame width 800mm

Colour: RAL 5010 (Gentian blue)

Battery Details:

Battery 1 = 1030 L 525 W 625 H

Battery 2 = 830 L 525 W 780 H

Battery 3 = 815 L 400 W 765 H

Battery 4 = 1201 L 340 W 785 H

Battery 5 = 1220 L 350 W 790 H

Battery 6 = 1025 L 850 W 780 H

Battery 7 = 1025 L 850 W 780 H

Battery 8 = 1220 L 350 W7 90 H

Battery 9 = 1220 L 425 W 765 H

Safety and Security Features:

1/ Additional 3 x proximity switch and reflector.

2/ Interlocking battery catch – interlock set at height of

battery.

3/ External contact relay to connect to the PPT.

4/ System status indicators (if LED is red the user has forgotten

something, green means everything is ok).

5/ Laser pointer.

6/ PSL code switch – multi user programmable with different

access codes.

7/ Yellow label around the emergency stop button.

8/ Bed status indicator the LED will be green in top and

bottom position and red when in between.

9/ Proxy sensor to detect magnet safety zone and enable PPT.

PPT Details:

Fork length: 1800mm

Fork outside width: 680mm

Fork spread: 165mm

PPT Lift: 122mm

Specification of the Powered Pallet Truck is the sole

responsibility of the customer. Acres Engineering can only offer

guidance and advice.

Note: Acres can only set the minimum roll off

height the maximum is determined by the

lift range on the PPT, note that on some

heavy batteries the PPT may relax (yield)

by up to 13mm.

Acres job number: AD-848-2016-01

Have a design and development project you want the Acres team to look at? Can’t see what you want? Need something different?

Acres Engineering is established as a leader in delivering bespoke creative engineered solutions. Many OEM’s and tier one/ two suppliers in aerospace, automotive, rail and power generation industries have chosen us as their solutions partner because of our innovative attitude towards individual challenges and commitment to continual improvement.