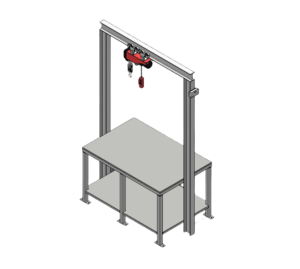

Heavy Duty Workbench with Hoist

Heavy Duty Workbench with Hoist

Scope We designed and manufactured a heavy-duty workbench with a hoist for our customer to help them safely and efficiently handle heavy materials in their workspace. Their operations required frequent lifting and positioning of large components, which was becoming a…

Read More

Scope

We designed and manufactured a heavy-duty workbench with a hoist for our customer to help them safely and efficiently handle heavy materials in their workspace. Their operations required frequent lifting and positioning of large components, which was becoming a strain on workers and slowing down productivity. By integrating a hoist into a durable workbench, we provided them with a solution that improves safety, reduces manual effort, and streamlines their workflow, allowing them to work more effectively and with greater precision.

Solution

Why

A heavy-duty workbench with a hoist is perfect for customers who need to lift and work on heavy items safely and efficiently. Whether in an auto repair shop, metalworking facility, or industrial setting, this setup reduces strain, improves productivity, and ensures precise handling of large or bulky materials. The combination of a sturdy work surface and an integrated hoist allows for easy positioning, assembly, and maintenance of heavy components, making it an essential tool for serious professionals.

A heavy-duty workbench with a hoist can be useful in various industries where heavy materials or equipment need to be lifted, positioned, or worked on safely. Some key industries include:

- Automotive & Mechanical Repair – Ideal for lifting engines, transmissions, and heavy parts for repairs and assembly.

- Manufacturing & Assembly – Helps workers handle heavy components in fabrication, welding, and production lines.

- Metalworking & Fabrication – Assists in maneuvering large metal pieces for cutting, welding, and finishing.

- Aerospace – Supports precise handling of aircraft components and assemblies.

- Construction & Engineering – Useful for assembling heavy equipment parts and structural components.

- Oil & Gas – Helps with the maintenance and assembly of heavy-duty drilling and extraction equipment.

- Agriculture & Heavy Equipment Maintenance – Supports the repair and servicing of tractors, machinery, and industrial tools.

- Defence & Military – Used for handling and maintaining heavy-duty machinery, weapons, and vehicle components.

This type of workbench is essential for industries that require safe, efficient lifting and positioning of large, bulky, or heavy objects.

Load tests and safe working loads (SWL) are critical for ensuring the safety, reliability, and efficiency of equipment like hoists and heavy-duty workbenches. Here’s why they matter:

Importance of Load Tests

- Ensures Structural Integrity – Verifies that the equipment can handle the expected load without failure.

- Prevents Accidents – Identifies weaknesses or defects before they lead to failures, reducing the risk of workplace injuries.

- Compliance with Safety Standards – Meets industry regulations (such as OSHA, ASME, or ISO) to ensure workplace safety.

- Increases Equipment Longevity – Helps detect wear and tear early, allowing for maintenance before critical failures occur.

- Builds User Confidence – Ensures workers can operate the equipment safely and efficiently without concerns about failure.

Importance of Safe Working Load (SWL)

- Defines Safe Usage Limits – Prevents overloading, which can cause structural damage or sudden failure.

- Protects Workers & Equipment – Ensures that hoists, benches, and other lifting devices operate within safe weight limits.

- Minimises Downtime – Prevents costly repairs or replacements due to overload-induced damage.

- Legal & Liability Compliance – Adhering to SWL ratings helps businesses avoid fines, lawsuits, and liability issues.

- Improves Operational Efficiency – Ensures that loads are managed safely, reducing the risk of delays or work stoppages.

By conducting regular load tests and adhering to safe working load limits, businesses can create a safer workplace, extend equipment life, and maintain compliance with industry safety standards. View our information guide below for more information:

Acres have a range of standard products but also support clients with custom machinery and medium-high volume products such as trolleys, stillages etc.

We have manufactured lots of different tables / workstations / workbenches for various industries.

We also manufacture access platforms, jigs and fixtures and many other types of production support solutions / products.

Talk to us today about your requirements: [email protected] / 01332695240 / Contact Us Form

Click on the icon to check out our social media! Please follow, like and share!

Want to know more about Acres Engineering?

We are based in the UK from our Headquarters in Derbyshire, England and have a European office in Malaga, Spain within the EU.

Find out more about where we have been and what we have been up to by checking out our latest blog posts.

Take a look at how we support of the Armed Forces, STEM/Schools and Charities.

As a world leader in our field, we offer a range of information guides sharing best practice with our clients.

We make it easy to engage with us, we are approved on: EcoVadis (external) / JOSCAR (external) / AVETTA (external) / COUPA (external) / SAP ARIBA (external) / DEEPSTREAM (external) ….you can download our BSI / Insurance certificates here.

![]()

![]()

![]()

Have a design and development project you want the Acres team to look at? Can’t see what you want? Need something different?

Acres Engineering is established as a leader in delivering bespoke creative engineered solutions. Many OEM’s and tier one/ two suppliers in aerospace, automotive, rail and power generation industries have chosen us as their solutions partner because of our innovative attitude towards individual challenges and commitment to continual improvement.