Kitting Media Support Stillages

Kitting Media Support Stillages

Scope One of our customers in the automotive manufacturing industry approached us with a challenge: their kitting process was inefficient due to disorganised components, frequent misplacements, and unnecessary handling time. They needed a tailored solution to streamline their workflow, improve…

Read More

Scope

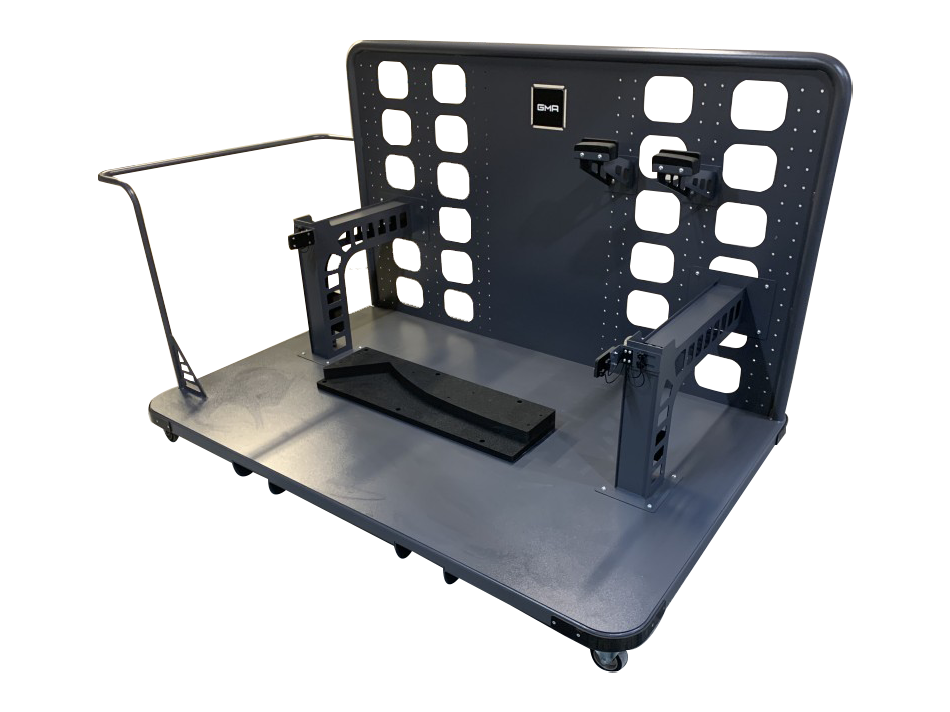

One of our customers in the automotive manufacturing industry approached us with a challenge: their kitting process was inefficient due to disorganised components, frequent misplacements, and unnecessary handling time. They needed a tailored solution to streamline their workflow, improve material accessibility, and enhance overall productivity. To address this, we designed a custom kitting media stillage that optimised storage, ensured easy identification of parts, and enabled seamless transport across their facility. This solution not only reduced downtime but also improved efficiency and workplace safety.

Solution

Project REF: AD-2156-2022-05-2 / 11571-P10

A kitting media stillage enhances operational efficiency by streamlining material handling and organisation. It reduces search time, minimises handling costs, improves inventory tracking, and optimises space with a stackable design. Additionally, it protects valuable components and can be customised to meet specific industry needs, making it an ideal solution for manufacturing, automotive, and aerospace operations.

A kitting media stillage can be used across various industries where organised material handling, efficient workflow, and secure storage are essential. Key industries include:

1. Automotive Manufacturing

- Organises and transports parts for vehicle assembly.

- Reduces production downtime by keeping components easily accessible.

2. Aerospace & Aviation

- Stores and transports precision components safely.

- Ensures efficient kitting for aircraft assembly and maintenance.

3. Logistics & Warehousing

- Optimises storage and retrieval processes for order fulfillment.

- Reduces handling time and improves inventory management.

4. Electronics & Technology

- Protects delicate components from damage during handling.

- Organises parts for streamlined assembly and production.

6. Defence & Military

- Stores and transports critical equipment and components securely.

- Streamlines logistics in high-demand environments.

Kitting media stillage enhance workshop efficiency with a customisable design, adjustable compartments, and various size options. Their mobility allows easy handling, while stackable and collapsible features optimise space. They improve workflow by keeping tools and materials organised, ensuring quick access. Additionally, they protect sensitive components, enhance safety, and adapt to diverse applications across multiple industries.

Having kitting media stillages is important because they streamline operations, improve organisation, and enhance efficiency in various industries. Here’s why they are essential:

1. Improved Workflow & Productivity

- Keeps all necessary components in one place, reducing time spent searching for parts.

- Ensures production kits are ready, minimising delays in assembly or manufacturing.

2. Reduced Handling & Labor Costs

- Simplifies material movement, reducing unnecessary handling and manual sorting.

- Helps workers quickly access the right parts, improving overall productivity.

3. Optimised Space & Organisation

- Stackable and compact designs maximise available workspace.

- Keeps work areas clean and structured, reducing clutter and enhancing safety.

4. Enhanced Inventory Control

- Allows for better tracking of materials, preventing shortages and overstocking.

- Reduces the risk of misplacing or losing critical components.

5. Protection & Safety

- Prevents damage to delicate or high-value components.

- Reduces the risk of workplace injuries caused by loose or misplaced items.

6. Industry Versatility & Customisation

- Can be tailored for various industries, including automotive, aerospace, and logistics.

- Designed with different load capacities, compartments, and mobility features to meet specific needs.

In short, kitting media stillages help businesses increase efficiency, reduce costs, and create a more organised and safer work environment.

Acres have a range of standard products but also support clients with custom machinery and medium-high volume products such as trolleys, stillages etc.

We have manufactured lots of different tables / workstations / workbenches for various industries.

We also manufacture access platforms, jigs and fixtures and many other types of production support solutions / products.

Talk to us today about your requirements: [email protected] / 01332695240 / Contact Us Form

Click on the icon to check out our social media! Please follow, like and share!

Want to know more about Acres Engineering?

We are based in the UK from our Headquarters in Derbyshire, England and have a European office in Malaga, Spain within the EU.

Find out more about where we have been and what we have been up to by checking out our latest blog posts.

Take a look at how we support of the Armed Forces, STEM/Schools and Charities.

As a world leader in our field, we offer a range of information guides sharing best practice with our clients.

We make it easy to engage with us, we are approved on: EcoVadis (external) / JOSCAR (external) / AVETTA (external) / COUPA (external) / SAP ARIBA (external) / DEEPSTREAM (external) ….you can download our BSI / Insurance certificates here.

![]()

![]()

![]()

Have a design and development project you want the Acres team to look at? Can’t see what you want? Need something different?

Acres Engineering is established as a leader in delivering bespoke creative engineered solutions. Many OEM’s and tier one/ two suppliers in aerospace, automotive, rail and power generation industries have chosen us as their solutions partner because of our innovative attitude towards individual challenges and commitment to continual improvement.