Loose Parts Storage

Loose Parts Storage

Loose Parts Storage Stillage – Enquiry REF: 2015-07-11818 The LPS – (Loose Parts Storage) stillage has been manufactured for a midlands based aerospace OEM for use with their gas turbine engines. The solution was developed to the following brief: “Create a simple product suitable…

Read More

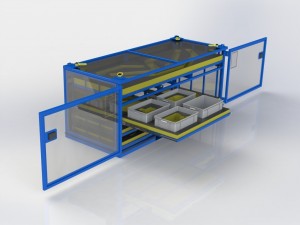

Loose Parts Storage Stillage – Enquiry REF: 2015-07-11818

The LPS – (Loose Parts Storage) stillage has been manufactured for a midlands based aerospace OEM for use with their gas turbine engines. The solution was developed to the following brief:

“Create a simple product suitable for transporting ‘loose components’

via airfreight. The loose components are dispatched with each engine

and should ideally be kept within a single unit”.

The team identified three key factors for project success:

Reduced Footprint, Reduced Weight, Increased Visibility.

The solution outline:

Designed for usability:

Ergonomics are critical when transporting components of this size. Our product has lockable double doors on two sides giving access to some components on one side and

some on the other. When open, the doors fold back against the side of the unit and lock in place. This prevents the risk of an individual, product or piece of equipment hitting into the doors. This also saves valuable floor space. Our design features pull out drawers fitted with heavy duty drawer runners with 100% extension to provide exceptional access to the components. The overall height of the unit is low eliminating the risk of high lifting.

Designed for airfreight:

Forklift truck pockets provide access from all sides of the product, reducing the risk of the

product being lifted incorrectly, which can often result in the damage of parts. In addition to this the unit is fitted with 4 heavy duty lifting eyes providing the ability to lift by crane.

Overall product size: 2622mm (W) x 2374mm (D) x 1195mm (O/A H)

Un-laden product weight: 674kg

Designed to be visual:

The panels are transparent for 100% visibility of components, reducing the risk of missing items. A4 document pockets are featured on the inside and outside of the doors allowing both logistics and component documentation to be stored and be accessible/available at point of use. Components are secured in engine-set foam inlays manufactured from profiled LD45 foam for non metal-to-metal contact and clear component identification. These sit in each drawer and are back filled with an opposing colour to act as a shadow board to further reduce the risk of missing items. Each profile is labelled with the component part number.

Designed to be futureproof:

Space is always a premium, but can become more so in the future. The stack-ability of the product allows up to three units to be stacked saving 12msq of floor space per stack. Its possible to reposition the drawers should the size of the components change in the future.

The profiled foam can also be replaced should components be modified, added or removed from the kit. With the flexibility of the design the product could be rolled out as a standard product to serve other engine types. Bump strip is fitted to the base of the unit reducing the risk of forklift truck damage. RFID ready, the solution can be retrofitted with the Acres RFID technology to enable parts tracking. Finally, the unit has been powder coated in RAL 20 D 45 Blue to suit the respective engines and provide a high quality, durable finish that will ensure product longevity.

Acres REF: AD-745-2015-07

Have a design and development project you want the Acres team to look at? Can’t see what you want? Need something different?

Acres Engineering is established as a leader in delivering bespoke creative engineered solutions. Many OEM’s and tier one/ two suppliers in aerospace, automotive, rail and power generation industries have chosen us as their solutions partner because of our innovative attitude towards individual challenges and commitment to continual improvement.