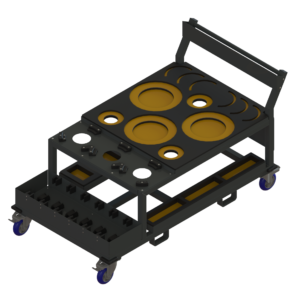

LPT removal ‘Point of use’ tooling trolley

LPT removal ‘Point of use’ tooling trolley

Scope: The make-up of this trolley will be a box section mild steel frame with a 1600mm wide upper shelf. All parts are to be foam lined to add extra protection but also adds a clear organisational element to the…

Read More

Our Aerospace client asked us to design and build a set of very specialised trolleys for use in their factory – The tooling housed with this trolley are all pieces of support equipment which are used inline with any workscopes that take place involving the LPT (Low Pressure Turbine).

Scope:

The make-up of this trolley will be a box section mild steel frame with a 1600mm wide upper shelf.

All parts are to be foam lined to add extra protection but also adds a clear organisational element to the trolley.

As well as castors and push-handle for maneuvering in the factory, the trolley includes forklift pockets for easy transportation.

Provided with full Load test certification to an SWL of 60kgs.

The in-house processes involved in manufacturing this are:

– Laser cut steel tube

– Laser cut steel sheet

– Waterjet cut foam profiles

– Press brake bending to form trays/boxes

– MIG welding

– Powder coating & Assembly

– 3D printed tool retaining fixtures

– Quality inspection & Load testing certification

Solution:

Drawing No: AD-2811-2025-03-1 – 12855-P5

What are the advantages of properly organised tooling trolleys in manufacturing environments?

1. Improved Efficiency and Workflow

-

Quick Access to Tools: Technicians and engineers can keep all required tools in one organised, mobile station, reducing the time spent searching for equipment.

-

Reduced Downtime: Since the trolley can be wheeled directly to the work area, maintenance and assembly tasks can begin immediately without multiple trips to a tool store.

-

Streamlined Processes: Tools can be arranged in a logical sequence according to the assembly or repair workflow, speeding up task execution.

2. Enhanced Organisation and Tool Management

-

Shadow Boards & Foam Inserts: Many aerospace/automotive trolleys feature cutouts or labeled slots, ensuring tools are always returned to their correct location.

-

Tool Accountability: Helps with FOD (Foreign Object Debris) control by making missing tools immediately noticeable, which is critical in both industries.

-

Inventory Control: Integrated tool tracking systems or RFID tags can automatically log tool usage and location.

3. Increased Safety and Compliance

-

FOD Prevention: Properly secured tools prevent accidental drops or tool loss, which is especially crucial in aerospace assembly lines.

-

Ergonomic Design: Adjustable heights and easy maneuverability reduce strain on workers, lowering the risk of injury.

-

Compliance with Standards: Many aerospace and automotive quality standards (like AS9100 or IATF 16949) emphasise tool traceability and maintenance — trolleys help achieve this.

4. Mobility and Flexibility

-

Adaptable to Various Workstations: Easily moved between assembly lines, maintenance bays, or inspection areas.

-

Support for Lean Manufacturing: Encourages a “tools at point of use” approach, aligning with 5S and Kaizen principles.

-

Customisable Layouts: Drawers, shelves, and holders can be tailored to specific tooling needs for a particular aircraft component or car subsystem.

5. Cost Savings

-

Reduced Tool Loss & Damage: Proper storage decreases wear and tear, extending tool life.

-

Lower Downtime Costs: Faster tool access means less idle time for skilled technicians, improving overall productivity.

-

Shared Resources: One well-equipped trolley can serve multiple technicians across shifts, minimising redundancy.

————————————————————————————————-

Acres have a range of standard products but also support clients with custom machinery and medium-high volume products such as trolleys, stillages etc.

We have manufactured lots of different tables / workstations / workbenches for various industries.

We also manufacture access platforms, jigs and fixtures and many other types of production support solutions / products.

Talk to us today about your requirements: [email protected] / 01332695240 / Contact Us Form

Click on the icon to check out our social media! Please follow, like and share!

Want to know more about Acres Engineering?

We are based in the UK from our Headquarters in Derbyshire, England and have a European office in Malaga, Spain within the EU.

Find out more about where we have been and what we have been up to by checking out our latest blog posts.

Take a look at how we support of the Armed Forces, STEM/Schools and Charities.

As a world leader in our field, we offer a range of information guides sharing best practice with our clients.

We make it easy to engage with us, we are approved on: EcoVadis (external) / JOSCAR (external) / AVETTA (external) / COUPA (external) / SAP ARIBA (external) / DEEPSTREAM (external) ….you can download our BSI / Insurance certificates here.

![]()

![]()

![]()

Have a design and development project you want the Acres team to look at? Can’t see what you want? Need something different?

Acres Engineering is established as a leader in delivering bespoke creative engineered solutions. Many OEM’s and tier one/ two suppliers in aerospace, automotive, rail and power generation industries have chosen us as their solutions partner because of our innovative attitude towards individual challenges and commitment to continual improvement.