Rack with Ball Transfer Units

Rack with Ball Transfer Units

Scope Design and manufacture a bespoke tooling rack to safely store wax pattern dies for the Wax Injection Area. Solution Project Ref: AD-2343-2023-09-1 / 11998-P1 This rack is designed with three sturdy shelves and is equipped with ball…

Read More

Scope

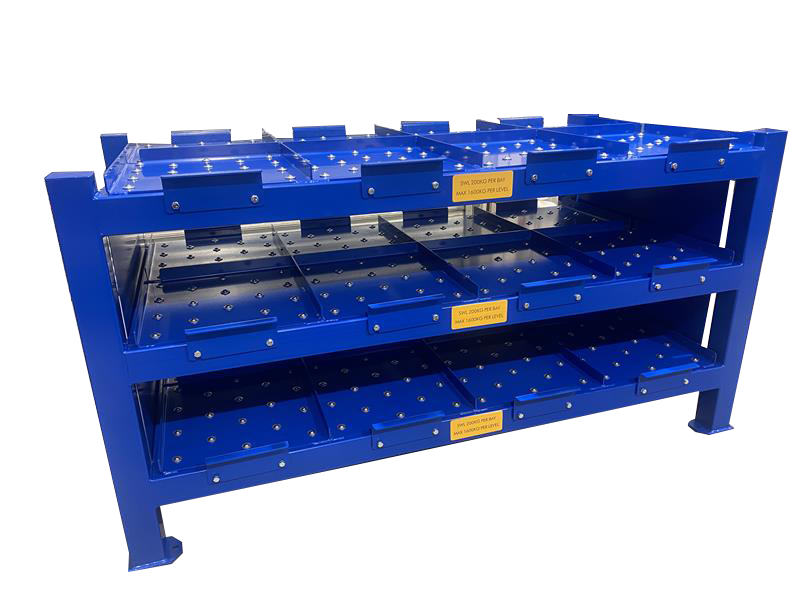

Design and manufacture a bespoke tooling rack to safely store wax pattern dies for the Wax Injection Area.

Solution

Project Ref: AD-2343-2023-09-1 / 11998-P1

This rack is designed with three sturdy shelves and is equipped with ball transfer units that allow for smooth and easy sliding of containers in and out. The 3 off levels deliver the ability to store 16 off 500mm x 500mm dies at up to 200kg per die on each level. The ball transfer units reduce friction, making the loading and unloading process more efficient, especially for heavier or bulkier containers. At the entry points, the rack features safety stops that prevent containers from accidentally falling out or sliding off the shelves, ensuring safe and controlled handling. These stops act as a secure barrier, keeping the containers in place once positioned on the shelf.

Custom racks can be used for a wide range of applications in various industries, primarily focused on improving storage, organisation, and efficiency. Here are some common uses:

- Tool Storage: Organise and protect specialised tools (e.g., CNC, EDM tools) for easy access and workflow efficiency.

- Parts and Component Storage: Safely store large or sensitive components (e.g., engine parts, aircraft parts) to reduce damage.

- Raw Material Storage: Store materials like steel beams, pipes, and sheet metal efficiently, saving space.

- Finished Product Storage: Hold finished products securely before they are shipped, organised by size or weight.

- Assembly Line Support: Keep parts and sub-assemblies ready at each workstation for efficient assembly line operations.

- Work-In-Progress (WIP) Storage: Store partially completed items between production stages to maintain organisation.

- Electronics and Circuit Boards: Store sensitive electronics with anti-static materials to prevent damage from electrostatic discharge.

- Shipping and Transport: Design racks for secure transport of goods and materials within or outside the facility.

- Maintenance and Repair Operations: Organise spare parts and tools for quick access during routine maintenance.

- Heavy-Duty Equipment Storage: Store large and heavy equipment securely with high load-bearing racks.

- Hazardous Material Storage: Safely store chemicals or flammable substances with specialized racks that meet safety standards.

- Mobile Storage Solutions: Equip racks with mobility features to easily transport tools or parts within a facility.

Custom racks provide significant benefits in manufacturing environments due to their ability to improve organisation, efficiency, and safety. Here’s why they are so advantageous:

- Optimised Storage and Space Utilisation: Custom racks are designed to fit specific tools, components, or materials, making the most efficient use of available space. They ensure that everything is stored in an organised and accessible manner, maximising floor space and reducing clutter, which is especially important in high-density production areas.

- Improved Workflow and Efficiency: By storing items in designated spots, custom racks make it easier for workers to locate tools or materials quickly, reducing downtime and improving the overall workflow. Workers can focus on production tasks rather than spending time searching for the right equipment, which leads to greater efficiency.

- Custom racks can also be designed for specific production processes, ensuring that the right tools and materials are readily available at each stage, further streamlining operations.

- Enhanced Safety: Properly designed custom racks reduce the risk of accidents by ensuring that heavy or sharp tools, hazardous materials, and other potentially dangerous equipment are stored securely. They help prevent items from falling, getting damaged, or causing injury to employees.

- In manufacturing environments where large, heavy components need to be stored or moved, custom racks ensure that these items are stored in a stable and safe manner, reducing the risk of injury or damage.

- Tool and Equipment Protection: Custom racks provide the necessary protection for delicate or expensive tools and equipment, such as precision instruments, EDM tooling, or specialised machinery parts. Storing these items correctly minimises the risk of damage from improper handling or storage, thus extending their lifespan and ensuring accuracy in production.

- Adaptability and Flexibility: Custom racks can be designed to be modular or adjustable, allowing manufacturers to modify them as production needs change. This flexibility is essential in dynamic manufacturing environments where product lines or processes may evolve, making it easy to adapt the storage solutions without requiring major overhauls.

- Cost-Effectiveness: Although custom racks may require an initial investment, they are cost-effective in the long term. By improving organization, reducing damage to tools, and speeding up workflow, custom racks help decrease operational costs. They also reduce the need for constant replacements or repairs of tools that may be damaged due to improper storage.

- Compliance with Industry Standards: In regulated industries like aerospace, pharmaceuticals, or automotive, specific storage and handling requirements must be met. Custom racks can be designed to comply with these stringent standards, ensuring the safe and legal storage of tools, materials, and components.

- Specialised Storage Needs: In industries like aerospace or electronics, where specialised or delicate equipment is used, custom racks provide the exact specifications required for storage. Whether it’s temperature control, anti-static protection, or shock absorption, custom racks can be tailored to meet these unique needs.

Custom racks are highly beneficial in manufacturing environments because they increase operational efficiency, improve safety, protect valuable tools and equipment, and provide a tailored solution that adapts to the specific needs of the production process.

Acres have a range of standard products but also support clients with custom machinery and medium-high volume products such as trolleys, stillages etc.

We have manufactured lots of different tables / workstations / workbenches for various industries.

We also manufacture access platforms, jigs and fixtures and many other types of production support solutions / products.

Talk to us today about your requirements: [email protected] / 01332695240 / Contact Us Form

Click on the icon to check out our social media! Please follow, like and share!

Want to know more about Acres Engineering?

We are based in the UK from our Headquarters in Derbyshire, England and have a European office in Malaga, Spain within the EU.

Find out more about where we have been and what we have been up to by checking out our latest blog posts.

Take a look at how we support of the Armed Forces, STEM/Schools and Charities.

As a world leader in our field, we offer a range of information guides sharing best practice with our clients.

We make it easy to engage with us, we are approved on: EcoVadis (external) / JOSCAR (external) / AVETTA (external) / COUPA (external) / SAP ARIBA (external) / DEEPSTREAM (external) ….you can download our BSI / Insurance certificates here.

![]()

![]()

![]()

Have a design and development project you want the Acres team to look at? Can’t see what you want? Need something different?

Acres Engineering is established as a leader in delivering bespoke creative engineered solutions. Many OEM’s and tier one/ two suppliers in aerospace, automotive, rail and power generation industries have chosen us as their solutions partner because of our innovative attitude towards individual challenges and commitment to continual improvement.