Tooling Rack

Tooling Rack

Scope Design and manufacture rack to hold tooling for HSD6 machine. The HSD6 machine is a high-speed EDM (Electrical Discharge Machining) drilling system primarily used in the aerospace and energy industries for precision drilling of cooling holes, slots, and other…

Read More

Scope

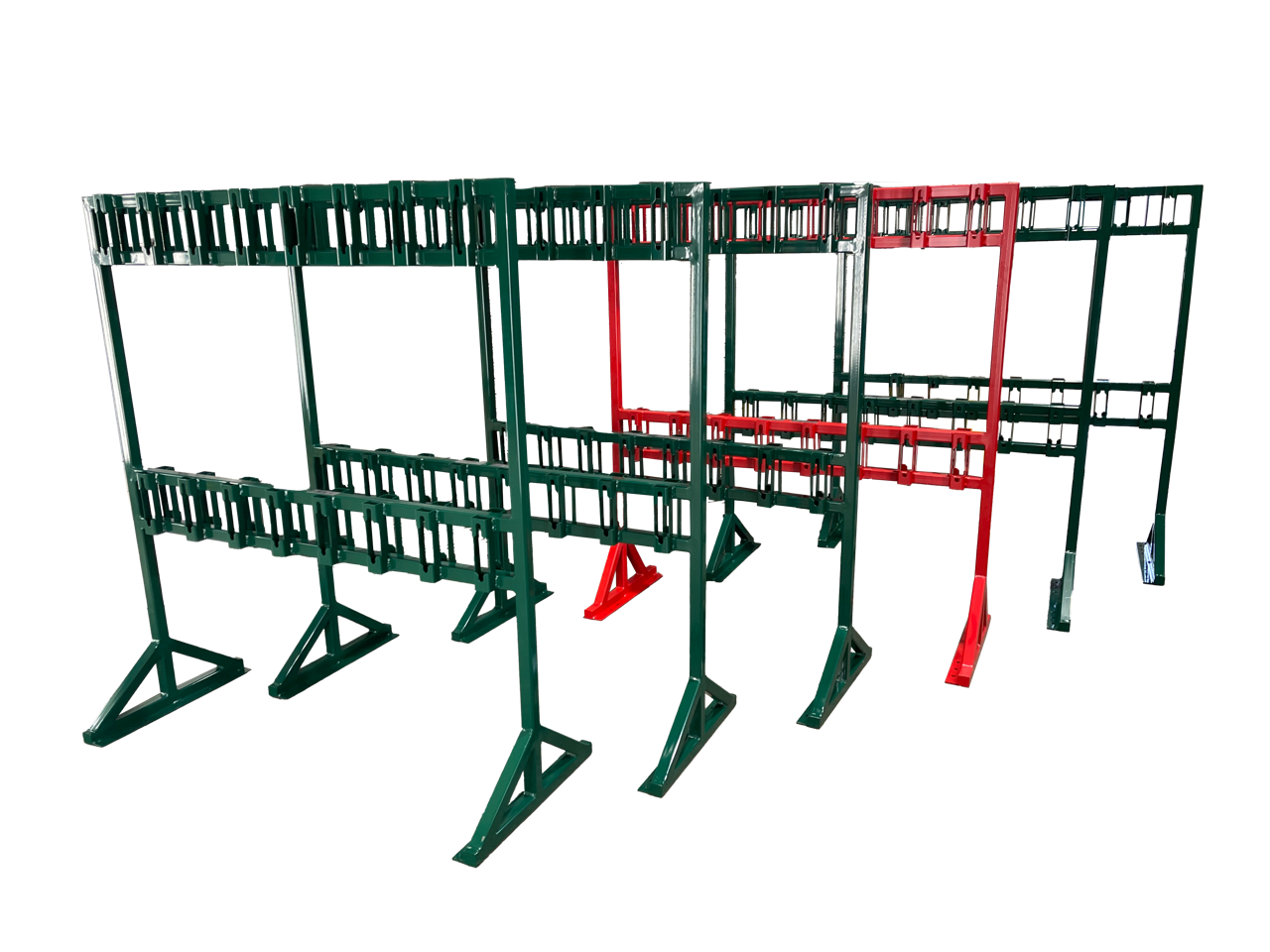

Design and manufacture rack to hold tooling for HSD6 machine. The HSD6 machine is a high-speed EDM (Electrical Discharge Machining) drilling system primarily used in the aerospace and energy industries for precision drilling of cooling holes, slots, and other intricate features on critical components like turbine blades, vanes, and segments. The system is designed to meet stringent metallurgical requirements for Aero and IGT (Industrial Gas Turbine) applications.

Solution

Project REF: AD-1135-2016-08-2 / 12669-P1

The racks are designed to securely store Winbro HSD6 tooling, preventing potential damage and ensuring proper organisation. The client has over 300 tools located across two separate areas on-site – the racks provide a convenient and efficient system for locating and accessing the correct tool promptly. Each tool is highly specialised and requires regular maintenance. These tools are frequently moved between production and maintenance, so quick identification is crucial for operational efficiency. Given the precision required for EDM machining, these tools are both sensitive and expensive, making proper storage essential. The racks meet all of the clients needs, ensuring the tools remain in optimal condition in a fast-paced production environment.

Key Features:

- Robust Design: Constructed with high-strength materials to withstand the rigours of industrial use.

- Ergonomic Tool Storage: The laser-cut locating plates allow for precise organization, making it easier for workers to access and store tools.

- Durable Finish: Powder-coated, the rack is designed for long-term use, resistant to scratches, impacts, and environmental wear.

- Aerospace Specific: Designed for a major UK aerospace client, specifically tailored for use in a precision casting environment.

Application and Usage:

While the HSD6 Tool Rack was designed for aerospace, its ergonomic design makes it applicable across other industries where efficient tool storage is required, such as automotive, rail, or manufacturing. It helps streamline production processes by ensuring tools are properly organised, minimising downtime, and maximising workplace efficiency.

This rack is not only sturdy but is also designed to handle the wear and tear of daily industrial use, making it an important addition to any high-performance industrial setting where organised, accessible tooling is critical to operational success.

Acres have a range of standard products but also support clients with custom machinery and medium-high volume products such as trolleys, stillages etc.

We have manufactured lots of different tables / workstations / workbenches for various industries.

We also manufacture access platforms, jigs and fixtures and many other types of production support solutions / products.

Talk to us today about your requirements: [email protected] / 01332695240 / Contact Us Form

Click on the icon to check out our social media! Please follow, like and share!

Want to know more about Acres Engineering?

We are based in the UK from our Headquarters in Derbyshire, England and have a European office in Malaga, Spain within the EU.

Find out more about where we have been and what we have been up to by checking out our latest blog posts.

Take a look at how we support of the Armed Forces, STEM/Schools and Charities.

As a world leader in our field, we offer a range of information guides sharing best practice with our clients.

We make it easy to engage with us, we are approved on: EcoVadis (external) / JOSCAR (external) / AVETTA (external) / COUPA (external) / SAP ARIBA (external) / DEEPSTREAM (external) ….you can download our BSI / Insurance certificates here.

![]()

![]()

![]()

Have a design and development project you want the Acres team to look at? Can’t see what you want? Need something different?

Acres Engineering is established as a leader in delivering bespoke creative engineered solutions. Many OEM’s and tier one/ two suppliers in aerospace, automotive, rail and power generation industries have chosen us as their solutions partner because of our innovative attitude towards individual challenges and commitment to continual improvement.