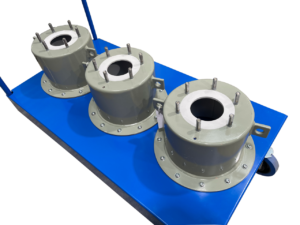

Trolley for Test Bushings

Trolley for Test Bushings

Scope: Develop solution for holding test equipment for the transformer manufacturing sector. Solution Project REF: AD-2497-2024-04-1 / 12556-P1 Having dedicated trolleys for test equipment, such as test bushings, in the transformer manufacturing sector offers several significant advantages: Improved Organisation and…

Read More

Scope:

Develop solution for holding test equipment for the transformer manufacturing sector.

Solution

Project REF: AD-2497-2024-04-1 / 12556-P1

Having dedicated trolleys for test equipment, such as test bushings, in the transformer manufacturing sector offers several significant advantages:

- Improved Organisation and Efficiency:

- Accessibility: Dedicated trolleys ensure that all necessary test equipment is organised and easily accessible. This reduces the time spent searching for tools and equipment, thereby increasing overall efficiency.

- Mobility: Test equipment can be easily transported to different areas of the manufacturing floor, facilitating quick and efficient testing processes.

- Enhanced Safety:

- Stability and Security: Properly designed trolleys can securely hold test equipment, reducing the risk of accidents caused by equipment falling or being improperly handled.

- Ergonomics: Trolleys can be designed to minimise the need for workers to lift heavy equipment, thereby reducing the risk of injury.

- Protection of Equipment:

- Damage Prevention: Dedicated trolleys can include features such as padding or custom compartments that protect sensitive test equipment from damage during transport and storage.

- Longevity: By protecting equipment from wear and tear, dedicated trolleys can extend the lifespan of test equipment, leading to cost savings.

- Consistency and Reliability:

- Standardisation: Having dedicated trolleys helps standardise the testing process, ensuring that all necessary equipment is always available and properly set up, leading to more reliable and consistent test results.

- Repeatability: Consistent use of the same equipment and setup can improve the repeatability of tests, which is crucial for maintaining quality standards in manufacturing.

- Improved Workflow and Productivity:

- Reduced Downtime: Quick access to well-organised test equipment can reduce downtime between manufacturing and testing processes, leading to higher productivity.

- Streamlined Processes: Dedicated trolleys can help streamline workflow by integrating testing as a seamless part of the manufacturing process, minimising interruptions and delays.

- Space Optimisation:

- Efficient Use of Space: Trolleys can be designed to maximise the use of available space, keeping the manufacturing floor uncluttered and more organised.

- Flexibility: Mobile trolleys can be easily reconfigured or moved to accommodate changing needs and layouts within the manufacturing facility.

- Cost-Effective:

- Reduced Equipment Loss: Having a dedicated place for each piece of test equipment reduces the likelihood of loss or misplacement, saving costs associated with replacing lost items.

- Minimised Maintenance Costs: Proper storage and handling reduce the likelihood of damage, thus lowering maintenance and repair costs.

Test bushings are essential components used in the transformer manufacturing sector for several critical purposes. Here’s a detailed overview of their functions and significance:

1. Electrical Insulation Testing:

- Dielectric Testing: Test bushings are used to assess the dielectric strength of the transformer insulation. This involves applying high voltage to determine if the insulation can withstand operational stresses without breaking down.

- Partial Discharge Testing: They help in detecting partial discharges within the insulation system. Partial discharges can indicate defects or weaknesses in the insulation, which could lead to failures if not addressed.

2. Performance Verification:

- AC and DC Testing: Test bushings are utilised in both AC and DC high voltage tests to verify the performance and reliability of transformers under different electrical conditions.

- Capacitance and Dissipation Factor (Tan Delta) Testing: They help measure the capacitance and dissipation factor of transformer bushings and insulation, which are critical parameters for assessing the insulation’s quality and detecting moisture or contamination.

3. Quality Assurance:

- Routine and Type Tests: Test bushings are used during routine and type tests to ensure that each transformer meets the required industry standards and specifications before it is approved for use.

- Factory Acceptance Testing (FAT): They are part of the comprehensive tests conducted before the transformer is shipped to the customer. This ensures that the transformer is free from manufacturing defects and is ready for installation.

4. Research and Development:

- Prototyping and Design Validation: In the R&D phase, test bushings are used to evaluate new transformer designs and materials. This helps manufacturers to innovate and improve transformer performance and reliability.

- Failure Analysis: They assist in conducting detailed failure analysis when a transformer fails. By simulating operational conditions, engineers can pinpoint the cause of failure and develop solutions to prevent recurrence.

5. Field Testing and Maintenance:

- On-Site Testing: Test bushings are also used for on-site testing of transformers that are already in service. This includes periodic testing to monitor the health and performance of the transformer.

- Condition Monitoring: They enable continuous or periodic monitoring of key parameters, allowing for predictive maintenance and early detection of potential issues.

Benefits of Using Test Bushings:

- Enhanced Safety: By ensuring transformers are thoroughly tested and meet safety standards, test bushings help prevent electrical failures and accidents.

- Improved Reliability: Transformers that pass rigorous testing are less likely to fail in service, leading to improved reliability of the power grid.

- Cost Savings: Early detection of potential issues through testing can prevent costly failures and reduce the need for expensive repairs or replacements.

- Regulatory Compliance: Using test bushings ensures that transformers comply with international and national standards, which is essential for market acceptance and legal compliance.

Acres have a range of standard products but also support clients with custom machinery and medium-high volume products such as trolleys, stillages etc.

We have manufactured lots of different tables / workstations / workbenches for various industries.

We also manufacture access platforms, jigs and fixtures and many other types of production support solutions / products.

Talk to us today about your requirements: [email protected] / 01332695240 / Contact Us Form

Click on the icon to check out our social media! Please follow, like and share!

Want to know more about Acres Engineering?

We are based in the UK from our Headquarters in Derbyshire, England and have a European office in Malaga, Spain within the EU.

Find out more about where we have been and what we have been up to by checking out our latest blog posts.

Take a look at how we support of the Armed Forces, STEM/Schools and Charities.

As a world leader in our field, we offer a range of information guides sharing best practice with our clients.

We make it easy to engage with us, we are approved on: EcoVadis (external) / JOSCAR (external) / AVETTA (external) / COUPA (external) / SAP ARIBA (external) / DEEPSTREAM (external) ….you can download our BSI / Insurance certificates here.

![]()

![]()

![]()

Have a design and development project you want the Acres team to look at? Can’t see what you want? Need something different?

Acres Engineering is established as a leader in delivering bespoke creative engineered solutions. Many OEM’s and tier one/ two suppliers in aerospace, automotive, rail and power generation industries have chosen us as their solutions partner because of our innovative attitude towards individual challenges and commitment to continual improvement.