Safe and Certified Welded Support Stand

Safe and Certified Welded Support Stand

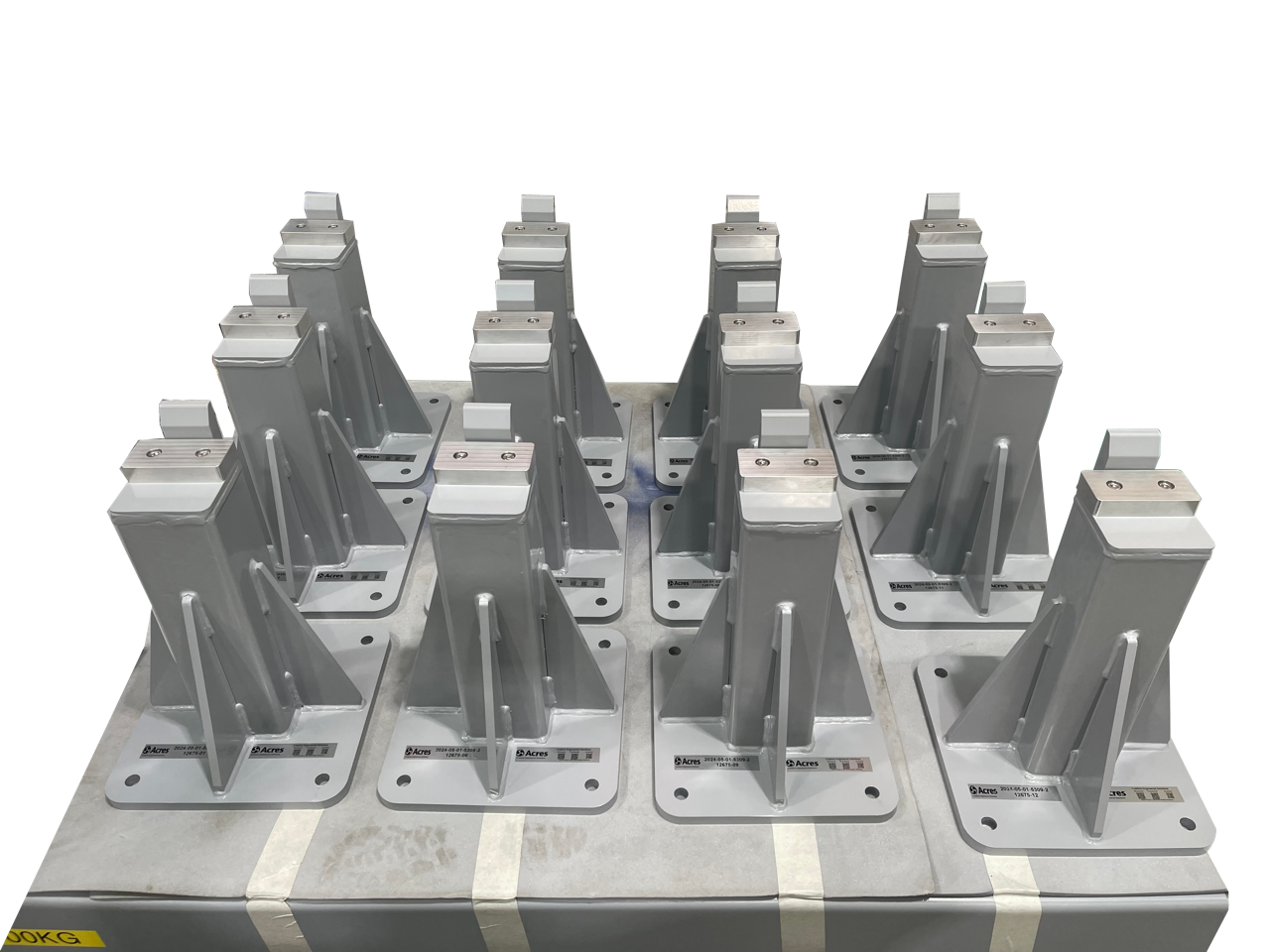

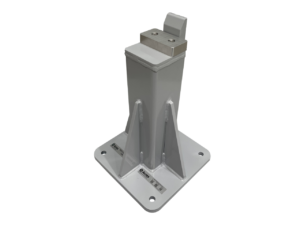

Scope Make to print. Manufacture train carriage support stand to clients 3D model provided. 10,000kg SWL. Solution Can you tell which one is CAD, and which one is real? Project REF: AD-2539-2024-06-1 / 12675-P1 Fully welded support stands used…

Read More

Scope

Make to print. Manufacture train carriage support stand to clients 3D model provided. 10,000kg SWL.

Solution

Can you tell which one is CAD, and which one is real?

Project REF: AD-2539-2024-06-1 / 12675-P1

Fully welded support stands used to hold train carriages during manufacture are designed to provide robust, stable, and reliable support to ensure that the carriages remain secure throughout the various stages of assembly and production. These stands are particularly important in the transportation and railway manufacturing industries due to the large size and weight of the carriages.

Key Features and Components of Fully Welded Support Stands:

- Robust Construction:

- Fully welded stands are typically constructed from heavy-duty steel, ensuring maximum strength and durability. The fully welded design means that all joints are permanently fused, enhancing the structural integrity of the stand. This eliminates the risk of weak points, making the stands capable of withstanding significant loads, including the heavy weight of train carriages.

- Load Capacity:

- These support stands are engineered to support extremely heavy loads, as train carriages can weigh several tons. The stands are designed with high load-bearing capacity to safely hold the carriages in place during the manufacturing process.

- The weight distribution capability of these stands is critical, as it helps prevent structural damage to the carriage during assembly and movement.

- Stability and Safety:

- Stability is a core requirement when supporting large and heavy objects like train carriages. These stands typically feature wide bases and reinforced frames to prevent tipping or shifting during manufacturing activities.

- Safety features such as non-slip surfaces or adjustable height mechanisms may be integrated to accommodate different carriage types and manufacturing conditions.

- Customisable Design:

- Depending on the specific needs of the manufacturer, fully welded support stands can be customised in terms of height, width, and load capacity. This allows them to be tailored for different stages of the assembly process, whether it’s for the initial frame construction or later stages such as painting or interior installation.

- Stands can also feature adjustable lifting points or pads to ensure the carriage is perfectly level and supported across multiple points, reducing stress on any single part of the structure.

- Corrosion and Wear Resistance:

- Since these support stands are often exposed to harsh environments in manufacturing plants, they are typically coated with protective finishes such as powder coating to enhance their resistance to corrosion, rust, and general wear and tear. This ensures long-term durability and reduces the need for frequent maintenance.

- Modular or Mobile Options:

- Some fully welded support stands may have modular designs or be equipped with wheels or rollers to facilitate easier movement of the train carriages around the factory. These mobile stands allow for flexibility during the assembly process, enabling manufacturers to move carriages between stations without the need for additional heavy-lifting equipment.

Specific Uses in Train Manufacturing:

- Assembly and Fabrication: Support stands hold the undercarriage and body components of the train during the initial fabrication stages, providing a stable platform for workers to assemble parts.

- Welding and Painting: During the welding of carriage sections or the application of coatings and paint, the stands keep the carriages at a convenient height and position for workers to safely complete their tasks.

- Inspection and Testing: The stands ensure that the carriages are securely supported during quality control inspections or performance testing, reducing the risk of movement or displacement that could affect the integrity of the process.

These stands are integral to the train carriage manufacturing process, ensuring safety, stability, and efficiency throughout the production cycle.

Support stands are versatile equipment used across various industries to provide stability and support for different types of loads or equipment. Here are some of their common uses:

- Construction and Industrial Work: In construction sites, support stands are used to hold materials like pipes, beams, and other heavy items in place, ensuring they are steady during operations like cutting, welding, or assembly. They are essential for maintaining safety and efficiency in heavy-duty work environments.

- Automotive Industry: In garages and automotive repair shops, support stands (often called jack stands) are used to safely support vehicles during maintenance or repair work. They keep the vehicle elevated and stable, allowing mechanics to work underneath without risk of the vehicle shifting or falling.

- Pipe and Tube Handling: Support stands are used to support pipes during installation or maintenance. They help in aligning pipes, facilitating safe and efficient handling, and ensuring that the pipes are held securely during work.

- Electrical and Telecommunications: In these sectors, support stands can be used to hold cables and other equipment in place while technicians work on installations or repairs, keeping the workspace organised and safe.

- Entertainment Industry: In the entertainment industry, support stands are often used to hold lighting equipment, speakers, or cameras in place. These stands ensure that the equipment is securely positioned for optimal performance during events or productions.

- Temporary Structure Support: For events or exhibitions, support stands are often used to support temporary structures like stages, booths, or tents, ensuring they remain stable and safe for use.

- Laboratories and Workshops: Support stands are also common in laboratory settings, where they are used to hold instruments or other apparatuses steady during experiments or when conducting detailed work that requires precision.

Overall, support stands play a critical role in providing stability, safety, and convenience across a wide range of applications, helping to ensure that operations are carried out smoothly and safely.

Acres have a range of standard products but also support clients with custom machinery and medium-high volume products such as trolleys, stillages etc.

We have manufactured lots of different tables / workstations / workbenches for various industries.

We also manufacture access platforms, jigs and fixtures and many other types of production support solutions / products.

Talk to us today about your requirements: [email protected] / 01332695240 / Contact Us Form

Click on the icon to check out our social media! Please follow, like and share!

Want to know more about Acres Engineering?

We are based in the UK from our Headquarters in Derbyshire, England and have a European office in Malaga, Spain within the EU.

Find out more about where we have been and what we have been up to by checking out our latest blog posts.

Take a look at how we support of the Armed Forces, STEM/Schools and Charities.

As a world leader in our field, we offer a range of information guides sharing best practice with our clients.

We make it easy to engage with us, we are approved on: EcoVadis (external) / JOSCAR (external) / AVETTA (external) / COUPA (external) / SAP ARIBA (external) / DEEPSTREAM (external) ….you can download our BSI / Insurance certificates here.

![]()

![]()

![]()

Have a design and development project you want the Acres team to look at? Can’t see what you want? Need something different?

Acres Engineering is established as a leader in delivering bespoke creative engineered solutions. Many OEM’s and tier one/ two suppliers in aerospace, automotive, rail and power generation industries have chosen us as their solutions partner because of our innovative attitude towards individual challenges and commitment to continual improvement.