What are Rotor Stands used for, and why is it important that they are safe and certified?

If you are interested in Rotor Stands, you have come to the right place! Get in touch to talk to one of our Engineers about your requirement: [email protected]

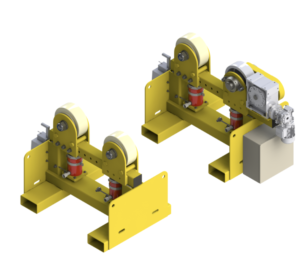

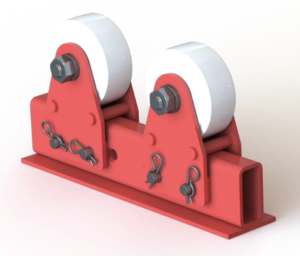

We have designed and manufactured a multitude of Rotor Support Stands, ranging from static to fully automated with height and width adjustment. Our stands can take loads as low as 2 tonnes (2000kg) up to and above 150 tonnes (150,000kg). Each stand is fully certified and comes with a SWL (safe working load) certificate.

So, what are rotor stands? The term “rotor stands” can refer to various structures or devices used to support, secure, or hold rotors in place. Rotors are rotating components found in various mechanical systems, such as engines, turbines, and electric motors. The stands provide a stable platform for the rotors during maintenance, assembly, or testing processes. The specific design and function of rotor stands may vary depending on the application and industry. Here are a few common scenarios where rotor stands might be used:

- Aerospace Industry – in the aerospace industry, rotor stands may be used for assembling and maintaining the rotors of helicopter or aircraft engines.

- Power Generation – in power plants, rotor stands could be used for supporting the rotors of generators or turbines during maintenance or inspection.

- Industrial Machinery – in various industrial applications, rotor stands could be utilised for handling and working on rotors in different types of machinery.

Rotor stands can be referred to in lots of different ways, such as the following.

- Rotor Support Stand

- Rotor Test Stand

- Rotor Balancing Stand

- Rotor Inspection Stand

- Spindle Stand

- Shaft Support Stand

- Rotating Equipment Stand

- Dynamic Balancing Stand

- Wind Turbine Rotor Stand

If you require this type of solution, or perhaps for another application, please get in touch with us at [email protected]

There are lots of great reasons to team up with Acres to ensure you have the right equipment for the job. Ensuring safe and certified equipment is used is a fundamental aspect of promoting workplace safety, ensuring product reliability, complying with regulations, and maintaining a positive reputation within the industry. It is an investment in the well-being of workers, the longevity of equipment, and the overall success of a business. Here’s just some of those benefits in more detail:

- Prevention of Accidents and Injuries – certified equipment is designed, tested, and manufactured to meet specific safety standards. This reduces the risk of accidents and injuries to the individuals operating the equipment.

- Compliance with Regulations – many industries have strict regulations and standards for equipment safety. Using certified equipment ensures compliance with these regulations, promoting a safer work environment.

- Consistent Performance – certified equipment undergoes rigorous testing to ensure its reliability and consistent performance. This is particularly important in critical applications where equipment failure could have severe consequences.

- Quality Assurance – certification processes often involve quality control measures, ensuring that the equipment meets established standards for design, construction, and performance.

- Reduced Liability – using certified equipment may reduce legal liabilities in the event of accidents or injuries. It demonstrates a commitment to safety and compliance with industry standards, which can be important in legal matters.

- Insurance Compliance – insurance providers often require businesses to use certified and safe equipment to qualify for coverage. Non-compliance may lead to higher premiums or the denial of coverage.

- Customer Confidence – using certified equipment can enhance the reputation of a business. Customers, clients, and partners often have confidence in organisations that prioritise safety and quality.

- Reduced Downtime and Maintenance Costs – certified equipment tends to be more reliable, leading to reduced downtime and lower maintenance costs over the long term.

Heres some previous rotor stands designed and manufactured by Acres Engineering:

Acres have a range of standard products but also support clients with custom machinery and medium-high volume products such as trolleys, stillages etc.

We have manufactured lots of different tables / workstations / workbenches for various industries.

We also manufacture access platforms, jigs and fixtures and many other types of production support solutions / products.

Talk to us today about your requirements: [email protected] / 01332695240 / Contact Us Form

Click on the icon to check out our social media! Please follow, like and share!

Want to know more about Acres Engineering?

We are based in the UK from our Headquarters in Derbyshire, England and have a European office in Malaga, Spain within the EU.

Find out more about where we have been and what we have been up to by checking out our latest blog posts.

Take a look at how we support of the Armed Forces, STEM/Schools and Charities.

As a world leader in our field, we offer a range of information guides sharing best practice with our clients.

We make it easy to engage with us, we are approved on: EcoVadis (external) / JOSCAR (external) / AVETTA (external) / COUPA (external) / SAP ARIBA (external) / DEEPSTREAM (external) ….you can download our BSI / Insurance certificates here.

![]()

![]()

![]()