Kitting Media

What is Kitting?

A kitting process in manufacturing is when a collection of parts and materials are grouped together in a single kit that has its own SKU number. These components are then delivered directly to the point-of-use, such as a specific part of the assembly line. Making use of a full kitting process in a warehouse can be extremely effective in improving your operations and efficiency.

Benefits of Kitting Processes

Kitting of components and the presentation of kits to a build line/ production area are essential in modern day manufacturing.

Decanting of components from external packaging into kitting media allows operatives to identify potential shortages and damage. This process also reduces the time required for skilled manufacturing staff to spend handling components. This delivers both a cost benefit and a process lead time benefit. Decanting components in a central location also allows packaging to be managed/ recycled effectively and efficiently. This can help companies hit their sustainability targets with less impacts to production.

Footprint reduction is also a typical benefit of investing in Acres kitting media if you have a space constraint, or are looking to squeeze in an additional capability.

Identifying shortages and damages at the kitting stage allows potential problems to be dealt with earlier in the process, rather than at point of requirement. This helps to minimise potential impacts to overall production lead time.

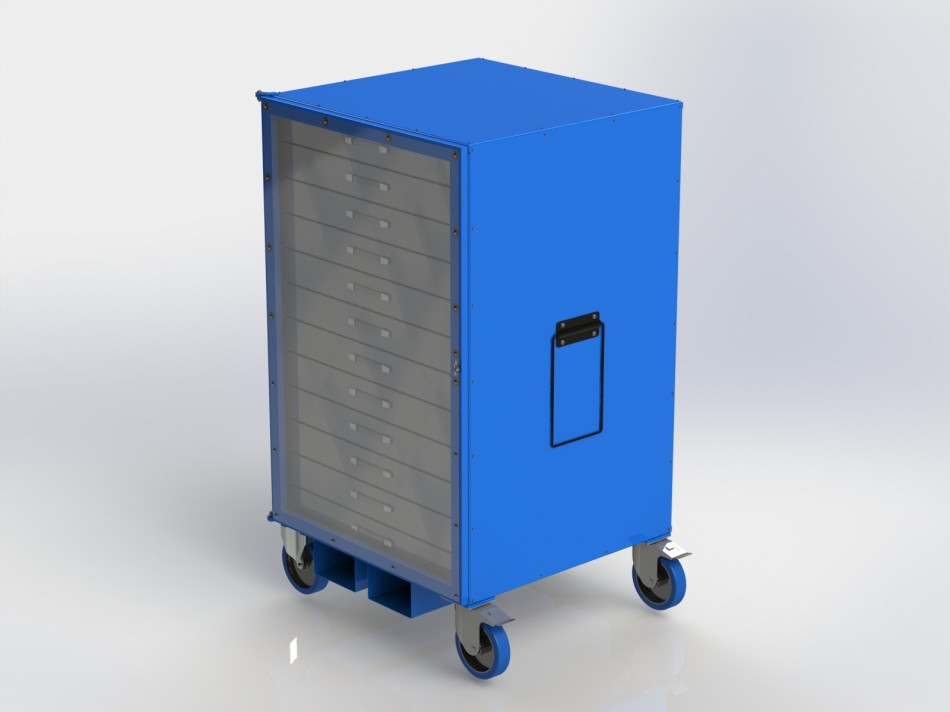

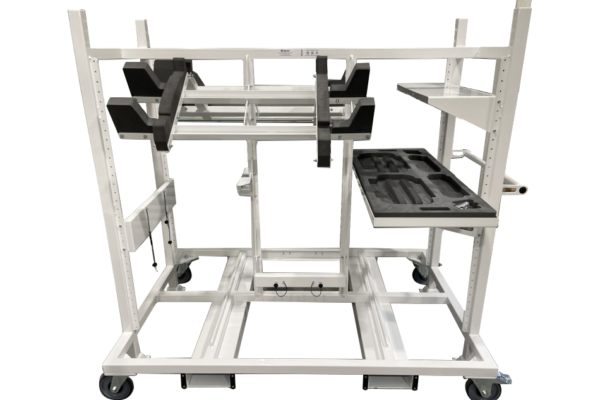

Once decanted components are kitted to Acres kitting media, the kitting media can then be either transported to a sequencing centre and then pulled into production or delivered directly to the production cell.

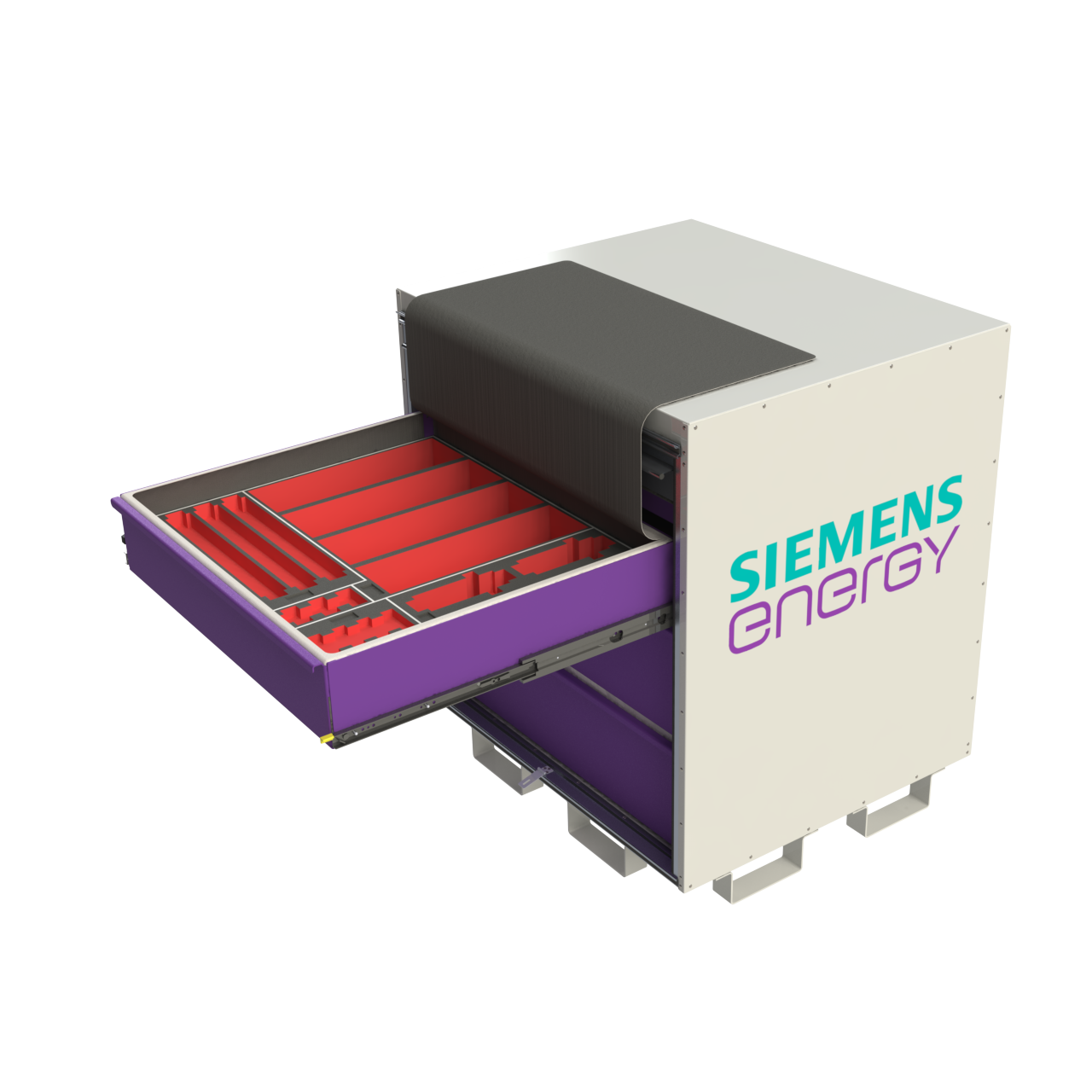

Acres Kitting Solutions

Acres designs kitting media based on the clients specific requirements. Considering the process before and after, the ideal batch size and the weights, materials, temperatures etc of components. These finite details deliver the full potential of a kitting exercise with additional benefits to quality, throughput, lead time etc.

Kitting media improves visibility in the manufacturing facility and the management of work in progress (WIP). Professional, fit for purpose, high quality kitting media demonstrates investment to employees, customers, investors and all other key stakeholders.

The combination of these benefits delivers expediential efficiency and in turn profit improvements. Typically investments in Acres kitting media has a short return on investment (ROI). Get in touch to discuss your kitting ambitions with our highly skilled and knowledgeable team at Acres Engineering.

Q&A

-Adam Payne, Director at TCMUK Limited

When did you first hear about continual improvement?

I started my career in Lean Thinking (or Lean Manufacturing) back in the early/mid 90’s as a Kaizen Engineer, being trained by Japanese Consultants and Pratt and Whitney Train the Trainer Programme, mixed with a number of Productivity Europe Course, Value Stream Mapping with SA Partners in 1995.

Do you think that a ‘kitting process’ is important to manufacturers, and if so why?

Depends on the individual application, but to answer “Absolutely”, it drives Efficiency, Quality, Controls Inventory, it reduces search time, it enhances workplace organisation, reduce space, introduces control.

Would you say you are passionate about lean manufacturing, and if so, why? What’s so exciting?

I’ve been passionate about Lean since my introduction to it as a Kaizen Engineer on my first Kaizen Event, this was an Achieving Quick Changeover Event on a Header machine making Aerospace bolts, the changeover was 8+ hours and our customer telling us we would have to buy another machine at £250K due to capacity constraints. We got the Change-Over down to 20 mins, and guess what, kitting was involved. I’ve been lucky enough to be mentored by some the best in Industry and I still continue to learn. I’ve been responsible for Growth, Strategy and Operations in a number of blue-chip organisations and have implemented Lean Thinking across all sectors all departments.

How do you think global manufacturing businesses will innovate and change coming out of COVID?

Innovation will come through Automation, Robotics, AI, AR, Big Data, driving Efficiencies. There will also need to be a strengthening of the supply chains, this is one area COVID has highlighted as a weakness.

Do you think it’s critical for manufacturers to have the right solution, not necessarily an off the shelf solution?

Definitely got to have the right solution, but it’s a mix of both, Off the shelf can certainly be considered, we’ve used Kanban wracks to feed in and out of cellular manufacturing for decades, I’ve been doing this recently with a few businesses in introducing one piece flow into their operations, but we also do need bespoke solutions to makes safe, enhance, improve, the process for our employees. We need to GO, LOOK and SEE where the work is being done and UNDERSTAND what improvements can and need to be made.