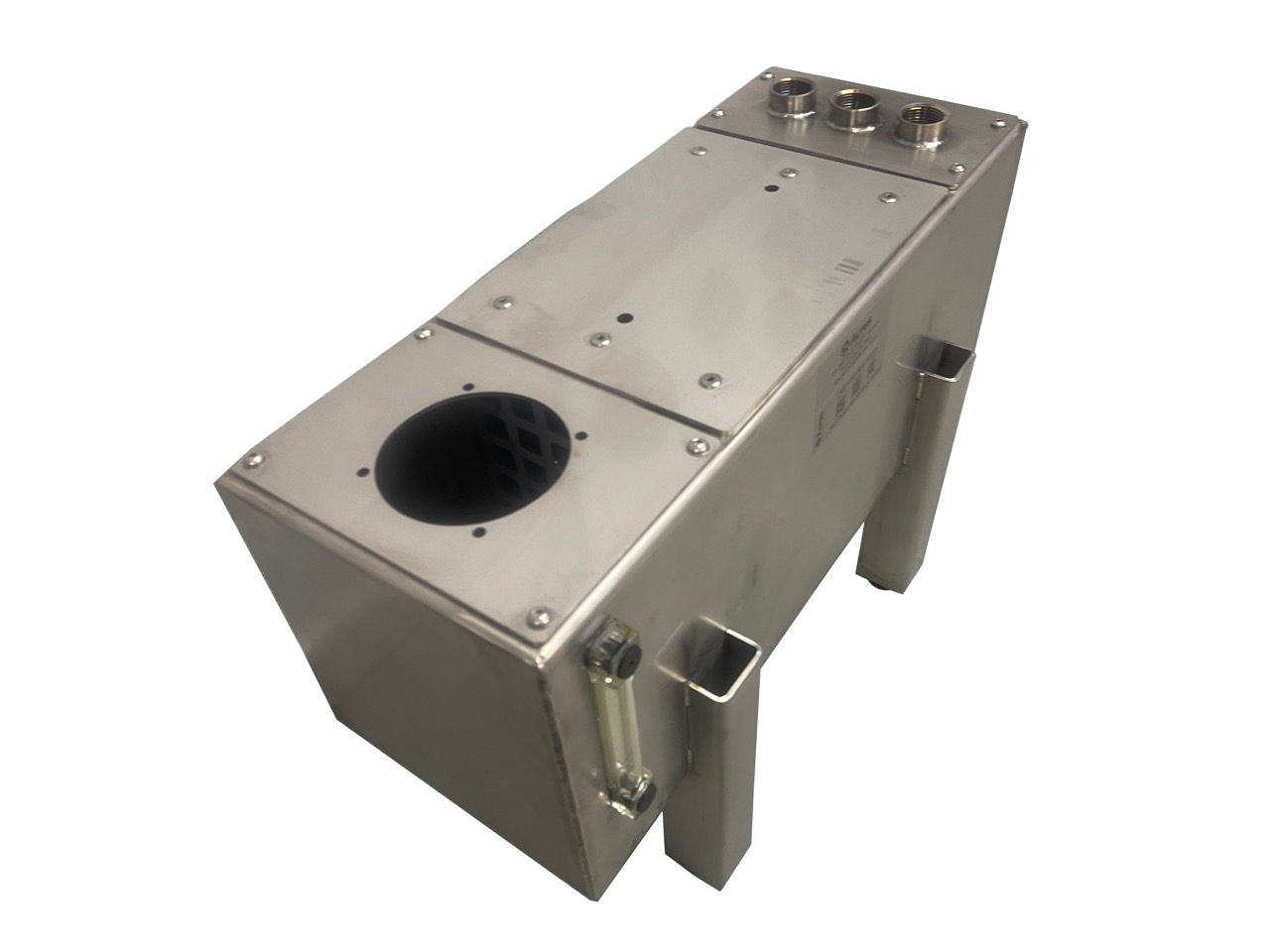

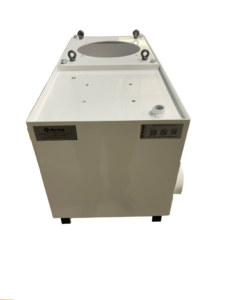

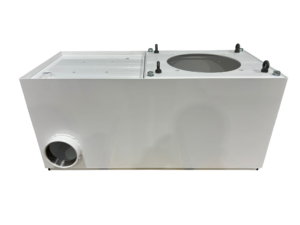

Return Tank for J&S Machines

Return Tank for J&S Machines

Specification Manufactured from mild steel Outer tank 2mm, lid – 3mm and internal supports from 8mm Powder coated Raise the tank 30mm off the floor Baffle plate inside – cut out left hand side Outlet pipe Handle on the lid…

Read More

Specification

Manufactured from mild steel

Outer tank 2mm, lid – 3mm and internal supports from 8mm

Powder coated

Raise the tank 30mm off the floor

Baffle plate inside – cut out left hand side

Outlet pipe

Handle on the lid section

Approximate overall size – 860mm (L) x 400mm (H) x 400mm (W)

Project REF: AD-2337-2023-08-2 / 12342-P1

A return tank in a machine typically refers to a reservoir or container used to collect and temporarily store fluids that are returned from a process. These fluids are often part of a closed-loop system where the fluid is used, returned, and then reused. Here are some common applications and functions of return tanks:

- Hydraulic Systems: In hydraulic machinery, return tanks collect hydraulic fluid that has been used to power various components. The fluid is then filtered, cooled if necessary, and recirculated back into the system.

- Cooling Systems: For cooling systems, such as those found in HVAC units or industrial cooling applications, a return tank collects coolant that has absorbed heat from the system. The coolant is then cooled down and pumped back to absorb more heat.

- Lubrication Systems: In lubrication systems, a return tank collects lubricant that has been used to reduce friction between moving parts. The lubricant is filtered to remove contaminants and then reused.

- Steam Systems: In steam heating or power generation systems, a condensate return tank collects condensed steam (water) that has been used for heating or powering turbines. This water is then treated and returned to the boiler for conversion back into steam.

- Chemical Processing: In chemical processing plants, return tanks collect chemicals that are used in reactions or processes. These chemicals are often filtered, purified, and reused in the system.

The main purposes of a return tank are to:

- Store Used Fluids: Temporarily hold fluids that have completed their cycle in the system.

- Allow for Cooling or Filtering: Provide a space where the fluid can be cooled, filtered, or otherwise treated before being reused.

- Maintain System Pressure and Flow: Help maintain consistent pressure and flow rates within the system by providing a buffer for fluid returning to the system.

Return tanks are integral to ensuring the efficiency, sustainability, and cost-effectiveness of various industrial and mechanical processes.

Various types of machines and systems across different industries utilise return tanks as part of their operation. Here are some examples:

- Hydraulic Machinery:

- Excavators

- Forklifts

- Hydraulic presses

- Industrial robots

- Cooling Systems:

- HVAC units (Heating, Ventilation, and Air Conditioning)

- Industrial chillers

- Power plant cooling systems

- Lubrication Systems:

- Large industrial machinery

- Automotive engines

- CNC (Computer Numerical Control) machines

- Conveyor systems

- Steam Systems:

- Steam boilers

- Power plants

- Steam heating systems in buildings

- Industrial process heating

- Chemical Processing Equipment:

- Chemical reactors

- Distillation columns

- Pharmaceutical processing equipment

- Food and beverage processing machinery

- Pneumatic Systems:

- Air compressors

- Pneumatic tools and machinery

- Industrial pneumatic systems

- Agricultural Machinery:

- Tractors with hydraulic implements

- Combine harvesters

- Sprayers and irrigation systems

- Marine and Offshore Equipment:

- Ship engines

- Offshore drilling rigs

- Hydraulic winches and cranes

- Manufacturing Equipment:

- Injection molding machines

- Die casting machines

- Metal stamping presses

- Refrigeration Systems:

- Commercial refrigeration units

- Industrial freezers

- Air conditioning systems

Return tanks in these machines serve to collect and manage the return flow of fluids, ensuring efficient operation, reducing waste, and maintaining system stability. They are crucial in systems where fluids are reused, helping to filter, cool, or otherwise treat the fluid before it is recirculated.

A J&S machine typically refers to a type of precision grinding machine produced by Jones & Shipman, a company known for its high-quality grinding and finishing equipment. These machines are used to achieve extremely tight tolerances and fine surface finishes, which are crucial in the aerospace industry where parts often need to meet stringent specifications for performance and safety.

Jones & Shipman (J&S) grinding machines are used for various applications, including:

- Surface Grinding: Ensuring flatness and smoothness of surfaces.

- Cylindrical Grinding: Producing precise cylindrical shapes and sizes.

- Internal Grinding: Refining the internal surfaces of components.

- Tool and Cutter Grinding: Sharpening and reconditioning cutting tools.

In the aerospace industry, these machines are essential for manufacturing critical components such as engine parts, landing gear, turbine blades, and other precision parts that require high accuracy and superior surface quality. The reliability and precision of J&S machines make them a preferred choice for aerospace manufacturers looking to meet the demanding standards of the industry.

Acres have a range of standard products but also support clients with custom machinery and medium-high volume products such as trolleys, stillages etc.

We have manufactured lots of different tables / workstations / workbenches for various industries.

We also manufacture access platforms, jigs and fixtures and many other types of production support solutions / products.

Talk to us today about your requirements: [email protected] / 01332695240 / Contact Us Form

Click on the icon to check out our social media! Please follow, like and share!

Want to know more about Acres Engineering?

We are based in the UK from our Headquarters in Derbyshire, England and have a European office in Malaga, Spain within the EU.

Find out more about where we have been and what we have been up to by checking out our latest blog posts.

Take a look at how we support of the Armed Forces, STEM/Schools and Charities.

As a world leader in our field, we offer a range of information guides sharing best practice with our clients.

We make it easy to engage with us, we are approved on: EcoVadis (external) / JOSCAR (external) / AVETTA (external) / COUPA (external) / SAP ARIBA (external) / DEEPSTREAM (external) ….you can download our BSI / Insurance certificates here.

![]()

![]()

![]()

Have a design and development project you want the Acres team to look at? Can’t see what you want? Need something different?

Acres Engineering is established as a leader in delivering bespoke creative engineered solutions. Many OEM’s and tier one/ two suppliers in aerospace, automotive, rail and power generation industries have chosen us as their solutions partner because of our innovative attitude towards individual challenges and commitment to continual improvement.