Kitting Stillage / Trolley

Kitting Stillage / Trolley

Scope We created a custom stillage based on the customer’s unique drawing to ensure that their specific storage and handling requirements were met. By using their design, we were able to provide a tailored solution that maximised efficiency, safety, and…

Read More

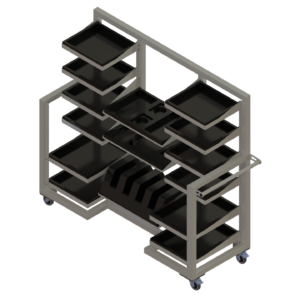

Our Supercar client asked us to build a very unique kitting stillage

Scope

We created a custom stillage based on the customer’s unique drawing to ensure that their specific storage and handling requirements were met. By using their design, we were able to provide a tailored solution that maximised efficiency, safety, and organisation for their needs. The stillage was built to fit their precise specifications, offering optimal storage capacity while maintaining ease of access and durability in their operational environment. This custom solution helps streamline their workflow and ensures long-term reliability.

This stillage features casters and a handle for easy movement and positioning on the production line, as well as multiple foam lined shelves for holding all required parts for this specific part of the production process. It was not a requirement in this case for the stillages to be stackable or liftable with a forklift. The shelves can also be moved on the frame or changed completely for adaptability.

Built from sturdy steel box-section and powder coated in RAL 9003 gloss to the customer’s requirements.

Solution

Project REF: AD-2839-2025-05-1 / 13243-P1

🚗 Improved Efficiency & Workflow

-

Just-in-time delivery: Kitting trolleys allow all parts needed for a particular build stage to be pre-picked and delivered together, eliminating time wasted searching for components.

-

Reduced line-side congestion: Instead of numerous small part bins cluttering the production area, a single organised trolley carries everything for the job.

-

Faster changeovers: When the next vehicle build starts, workers simply swap out the trolley, significantly reducing downtime between builds.

📦 Enhanced Organisation & Quality Control

-

Error reduction: Pre-kitting parts reduces the chance of picking errors or missing components, which is critical in high-value supercar production.

-

Visual control: The stillage can be clearly labelled with build numbers or colour-coded sections, making it obvious if something is missing.

-

Component protection: Custom inserts or foam can be added to protect delicate or high-value parts during transport.

⚙️ Ergonomics and Safety Benefits

-

Easy manoeuvrability: Wheeled design allows staff to move heavy or bulky kits without lifting, reducing manual handling injuries.

-

Improved accessibility: Proper shelf heights and open design let workers access parts quickly and safely without awkward reaching or bending.

-

Reduced fork truck traffic: Fewer forklift runs on the shop floor improves safety and reduces risk of damage to vehicles or parts.

🔁 Flexibility and Reusability

-

Modular design: Stillages can be configured for different car models or production stages, making them adaptable to changes in production.

-

Reusable asset: Built to be durable, they can be reused across multiple builds, reducing packaging waste and costs over time.

♻️ Lean Manufacturing & Sustainability Gains

-

Supports lean principles: Aligns with pull-based production by delivering only what is needed, when it is needed.

-

Less packaging waste: Reduces use of single-use cardboard or plastic packaging for line-side delivery.

-

Improved inventory control: Makes it easier to track parts usage and replenish stock accurately.

————————————————————-

Acres have a range of standard products but also support clients with custom machinery and medium-high volume products such as trolleys, stillages etc.

We have manufactured lots of different tables / workstations / workbenches for various industries.

We also manufacture access platforms, jigs and fixtures and many other types of production support solutions / products.

Talk to us today about your requirements: [email protected] / 01332695240 / Contact Us Form

Click on the icon to check out our social media! Please follow, like and share!

Want to know more about Acres Engineering?

We are based in the UK from our Headquarters in Derbyshire, England and have a European office in Malaga, Spain within the EU.

Find out more about where we have been and what we have been up to by checking out our latest blog posts.

Take a look at how we support of the Armed Forces, STEM/Schools and Charities.

As a world leader in our field, we offer a range of information guides sharing best practice with our clients.

We make it easy to engage with us, we are approved on: EcoVadis (external) / JOSCAR (external) / AVETTA (external) / COUPA (external) / SAP ARIBA (external) / DEEPSTREAM (external) ….you can download our BSI / Insurance certificates here.

![]()

![]()

![]()

Have a design and development project you want the Acres team to look at? Can’t see what you want? Need something different?

Acres Engineering is established as a leader in delivering bespoke creative engineered solutions. Many OEM’s and tier one/ two suppliers in aerospace, automotive, rail and power generation industries have chosen us as their solutions partner because of our innovative attitude towards individual challenges and commitment to continual improvement.