Rocker Trolley

Rocker Trolley

Scope Design and manufacture a trolley to hold automotive rocker panels. Each trolley to hold 16 rocker components reducing the risk of damage (read our information guide on part protection). The trolley was designed with a handle to act as…

Read More

Scope

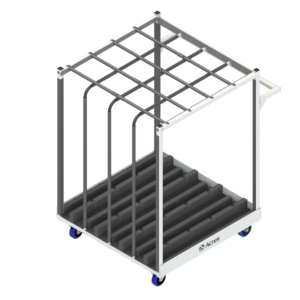

Design and manufacture a trolley to hold automotive rocker panels. Each trolley to hold 16 rocker components reducing the risk of damage (read our information guide on part protection).

The trolley was designed with a handle to act as a bumper when used for parking and storing the components. The foam panels in the base of the trolley (cut on Acres waterjet cutting machine) hold the components in place whilst also protecting them. The high quality product with a powder coated finish features castors and visual management stickers to ensure it is operated correctly.

Solution

Project REF: AD-2448-2024-01-3 / 12427-P1

Why

Trolleys are an essential component of modern manufacturing operations, providing a simple yet effective solution for material handling that boosts productivity, ensures safety, and optimises workflow within manufacturing environments. Manufacturing companies use trolleys for several practical reasons that enhance efficiency, safety, and operational smoothness within their facilities. Here are some of the key reasons why trolleys are a vital tool in manufacturing settings:

- Material Handling Efficiency: Trolleys are used to transport goods, materials, and equipment across the manufacturing floor. They enable the movement of heavy or bulky items that might be difficult or unsafe to carry manually. This reduces the time and effort needed to move items and increases overall workflow efficiency.

- Worker Safety: By using trolleys to move items, companies reduce the physical strain on workers, which can lead to injuries such as back strain or muscle fatigue. This not only helps in maintaining the health and safety of the workforce but also reduces the likelihood of work-related injuries, which can lead to lost time and increased compensation claims.

- Increased Productivity: Trolleys streamline the process of moving materials from one place to another, allowing workers to transport multiple items at once or handle heavier loads than they could manually. This helps in keeping production lines supplied and removes bottlenecks caused by slower manual handling methods.

- Versatility: Trolleys are available in various designs to suit different needs within the manufacturing environment. Whether it’s flatbed trolleys for large items, shelf trolleys for organising smaller parts, or specialised trolleys designed for specific industries, there is a wide range of options that can be tailored to specific tasks.

- Space Optimisation: Efficient use of space is crucial in manufacturing. Trolleys help in organising and transporting materials more compactly and can be easily moved out of the way when not in use, unlike permanent structures or heavy machinery that occupy fixed spaces.

- Damage Reduction: Using trolleys for transportation within a manufacturing plant reduces the risk of damaging materials and products. The controlled and stable platform of a trolley means items are less likely to be dropped or mishandled than if carried manually.

- Cost-Effectiveness: While providing significant operational benefits, trolleys are a relatively low-cost investment compared to other machinery. They are also durable and require minimal maintenance, offering a cost-effective solution for internal logistics.

Acres design and manufacture lots of different trolleys.

We also manufacture access platforms, jigs and fixtures and many other types of product.

Talk to us today about your requirements: [email protected] / 01332695240 / Contact Us Form

Want to know more about Acres Engineering?

Check out our latest blog posts.

We post about our support of the Armed Forces, STEM and Charity.

We offer a range of information guides.

We make it easy to engage with us, we are approved on: JOSCAR / AVETTA / COUPA / SAP ARIBA / DEEPSTREAM….you can download our BSI / Insurance certificates here.

Have a design and development project you want the Acres team to look at? Can’t see what you want? Need something different?

Acres Engineering is established as a leader in delivering bespoke creative engineered solutions. Many OEM’s and tier one/ two suppliers in aerospace, automotive, rail and power generation industries have chosen us as their solutions partner because of our innovative attitude towards individual challenges and commitment to continual improvement.