Suspension Kit Stillages

Suspension Kit Stillages

Scope Design and manufacture a solution to transport and store suspension kits ready for pre-assembly. This stillage was designed for front/ rear RH suspension kits for the automotive sector. This type of product is sometimes referred to as a stillage,…

Read More

Scope

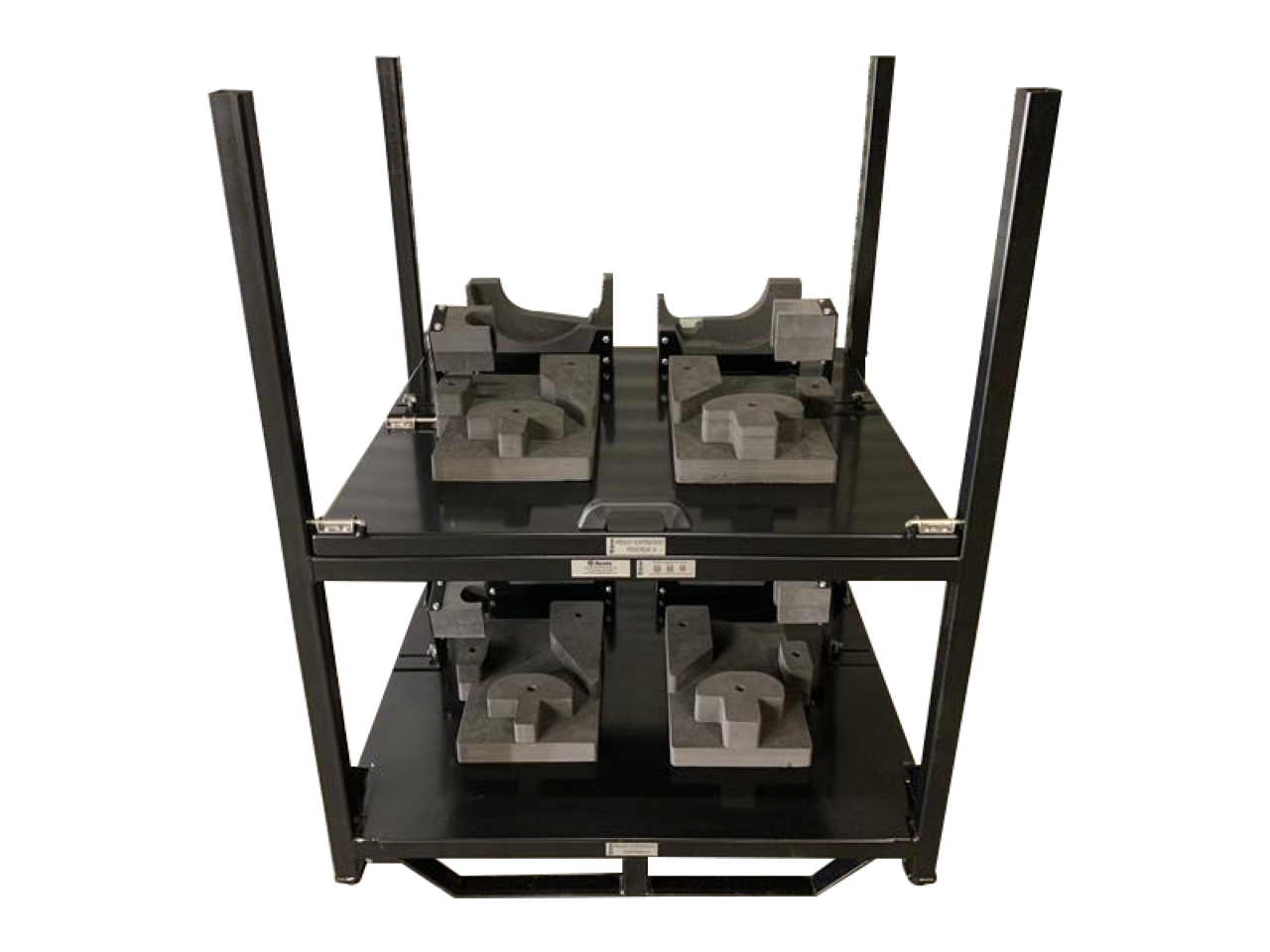

Design and manufacture a solution to transport and store suspension kits ready for pre-assembly. This stillage was designed for front/ rear RH suspension kits for the automotive sector. This type of product is sometimes referred to as a stillage, or sometimes as kitting media. The solution had foam profile pads to support the components without causing damage produced on Acres waterjet cutting machine. The top shelf, fitted with a gas strut hinges open to provide improved ergonomic access to the lower shelf. The solution is stackable to reduce footprint.

Solution

Project Ref: AD-2183-2022-08-1 / 11540-P8

Why

Check out our information guide on why and when to choose a stillage over a pallet and, why it is important to protect components.

What are car suspension kits? They are collections of parts that control a vehicle’s movement over various surfaces, enhancing its handling and performance. Key components typically include springs, shock absorbers or struts, linkages, and bushings. These elements work together to absorb road shocks, maintain wheel alignment, and improve overall driving stability and comfort. The specific makeup of a suspension kit can vary, aiming to boost performance, adjust height, or enhance ride quality.

For car manufacturers, protecting parts, like suspension kits, and presenting them correctly on the assembly line is crucial for several reasons:

- Quality Assurance: Ensures parts are undamaged and functional, leading to reliable and attractive vehicles.

- Efficiency: Streamlines manufacturing processes, reduces errors, and decreases production time and costs.

- Safety: Prevents workplace accidents by ensuring safe handling and installation of parts.

- Cost Reduction: Minimises the need for replacements and repairs, reducing overall production expenses.

- Customer Satisfaction: Improves the final product quality, enhancing customer satisfaction and bolstering the brand’s reputation.

This meticulous approach to part handling and assembly is fundamental to achieving high standards in vehicle production.

Acres have a range of standard products but also support clients with custom machinery and medium-high volume products such as trolleys, stillages etc.

We have manufactured lots of different stillages for various industries.

We also manufacture access platforms, jigs and fixtures and many other types of production support solutions / products.

Talk to us today about your requirements: [email protected] / 01332695240 / Contact Us Form

Want to know more about Acres Engineering?

Find out more about where we have been and what we have been up to by checking out our latest blog posts.

Take a look at how we support of the Armed Forces, STEM/Schools and Charities.

As a world leader in our field, we offer a range of information guides sharing best practice with our clients.

We make it easy to engage with us, we are approved on: JOSCAR / AVETTA / COUPA / SAP ARIBA / DEEPSTREAM….you can download our BSI / Insurance certificates here.

Please follow us on social media and like / share: Facebook / LinkedIn / X / Insta

Manufactured in the UK from our Headquarters in Derbyshire, England.

European office in Malaga, Spain.

Have a design and development project you want the Acres team to look at? Can’t see what you want? Need something different?

Acres Engineering is established as a leader in delivering bespoke creative engineered solutions. Many OEM’s and tier one/ two suppliers in aerospace, automotive, rail and power generation industries have chosen us as their solutions partner because of our innovative attitude towards individual challenges and commitment to continual improvement.