Draining Bench with Fluid Capture

Draining Bench with Fluid Capture

Scope: Provide a workbench to be used for draining components that have been cleaned with oil ready for inspection. The inspection bench must capture the oil, reducing the risk of spillages on the floor. The bench is to be situated…

Read More

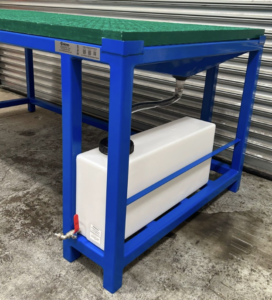

Check out this Draining Bench with Fluid Capture for Inspecting Hydraulic Components.

Scope:

Provide a workbench to be used for draining components that have been cleaned with oil ready for inspection. The inspection bench must capture the oil, reducing the risk of spillages on the floor. The bench is to be situated in the clients goods inwards department.

Solution:

Manufacture the workbench to approx. dimensions of unit: 2000m x 1000mm x 850mm H. The bench is manufactured from 50mm x 50mm box section and 2mm sheet. It is assembled with 38mm GRP fibre grid surface and a 30L holding tank fitting with a drain tap. This bench can hold 12 units weighing 150kg each.

At Acres Engineering we manufacture work benches of this nature in many shapes and sizes with a multitude of features.

Why do we manufacture bespoke ‘fit for purpose’ benches for our clients?

Having a fit-for-purpose workbench is important for several reasons, and it contributes to the overall efficiency, safety, and productivity of a workspace. Here are some key reasons why a fit-for-purpose workbench is crucial:

- Task Efficiency: A workbench that is specifically designed for the tasks at hand allows workers to perform their duties more efficiently. The design and features of the workbench should match the requirements of the job, providing the necessary space, organisation, and tools for the tasks being performed.

- Ergonomics: A fit-for-purpose workbench takes into consideration ergonomic principles, ensuring that the height, layout, and features of the bench are conducive to comfortable and safe working conditions. This can help prevent musculoskeletal issues and improve overall worker well-being.

- Tool and Equipment Integration: Different tasks require specific tools and equipment. A well-designed workbench includes features such as built-in storage, power outlets, and tool holders that allow for easy access to necessary tools, promoting organisation and efficiency.

- Safety: A workbench that is fit for its intended purpose is designed with safety in mind. It should have the necessary structural integrity, stability, and features to prevent accidents and injuries. This includes considerations for load capacity, anti-slip surfaces, and proper ventilation if dealing with hazardous materials.

- Durability and Longevity: A fit-for-purpose workbench is constructed from materials that can withstand the demands of the tasks performed on it. This ensures durability and longevity, reducing the need for frequent replacements and maintenance.

- Customisation: Workbenches that are fit for their purpose often allow for customisation to meet specific workflow requirements. This adaptability is crucial in environments where tasks may vary, and having a bench that can be configured to different needs enhances flexibility.

- Organisation and Space Utilisation: An appropriately designed workbench contributes to a well organised workspace. Efficient use of space, storage solutions, and a logical layout help minimise clutter, reduce the risk of accidents, and streamline work processes.

- Workflow Optimisation: A well-designed workbench contributes to workflow optimisation by facilitating a smooth and organised process. This is particularly important in manufacturing, assembly, or repair environments where the efficiency of operations directly impacts productivity.

In summary, a fit-for-purpose workbench is essential for creating a workspace that is efficient, safe, and conducive to optimal performance. It addresses specific task requirements, promotes ergonomics, integrates necessary tools and equipment, prioritises safety, ensures durability, allows for customisation, and contributes to overall organization and workflow optimisation.

Project REF: AD-2358-2023-10-1 / 12051-P1

Check out other racks here: https://acres.engineering/solutions/?product_type=workbenches-and-workstations

We manufacture lots of different types of workbenches for lots of different applications. Some of these include:

- Assembly Workbenches:

- Designed for assembling components or products.

- Often feature a flat, sturdy surface for easy assembly and organization.

- Woodworking Workbenches:

- Tailored for woodworking tasks such as cutting, shaping, and assembling wood.

- Typically include features like vices, bench dogs, and holes for holdfasts.

- Electronics Workbenches:

- Geared towards electronic assembly, testing, and repair.

- May include features such as ESD (electrostatic discharge) protection and built-in power outlets.

- Garage Workbenches:

- Used in home garages or workshops for various tasks, including DIY projects and vehicle maintenance.

- Often include storage drawers or shelves for tools and supplies.

- Industrial Workbenches:

- Designed for heavy-duty use in industrial settings.

- Feature robust construction, high load capacity, and may include additional accessories for specific tasks.

- Laboratory Workbenches:

- Used in scientific laboratories for conducting experiments and research.

- Often include chemical-resistant surfaces, storage for lab equipment, and may be height-adjustable.

- Metalworking Workbenches:

- Tailored for tasks involving metal fabrication, welding, or machining.

- Usually made from durable materials that can withstand high heat and heavy loads.

- Packing and Shipping Workbenches:

- Designed for packaging and shipping operations.

- Include features like built-in scales, packing material storage, and areas for labeling.

- Adjustable Height Workbenches:

- Allow users to adjust the height of the work surface to accommodate different tasks or preferences.

- Useful for promoting ergonomic working conditions.

- Foldable or Portable Workbenches:

- Designed to be easily folded or disassembled for portability and storage.

- Ideal for those with limited space or for on-the-go projects.

- Tool Storage Workbenches:

- Combine a work surface with built-in tool storage solutions.

- Allow for easy access to tools and materials during tasks.

- Electronic Testing Benches:

- Configured for testing electronic components and devices.

- May include features like power supplies, oscilloscope mounts, and signal generators.

- Cleanroom Workbenches:

- Used in environments with strict cleanliness requirements, such as semiconductor manufacturing or pharmaceutical labs.

- Feature smooth, easy-to-clean surfaces and may have integrated filtration systems.

- Potters’ Benches:

- Designed for pottery and clay work.

- Often include features like a splash pan and storage for clay and tools.

These are just a few examples, and workbenches can be further customised or specialised based on specific industry needs or individual preferences. Choosing the right type of workbench depends on the tasks to be performed and the environment in which it will be used.

We also manufacture access platforms, jigs and fixtures and many other types of product.

Talk to us today about your requirements: [email protected] / 01332695240 / Contact Us Form

Want to know more about Acres Engineering?

Check out our latest blog posts.

We post about our support of the Armed Forces, STEM and Charity.

We offer a range of information guides.

We make it easy to engage with us, we are approved on: JOSCAR / AVETTA / COUPA / SAP ARIBA / DEEPSTREAM….you can download our BSI / Insurance certificates here.

Have a design and development project you want the Acres team to look at? Can’t see what you want? Need something different?

Acres Engineering is established as a leader in delivering bespoke creative engineered solutions. Many OEM’s and tier one/ two suppliers in aerospace, automotive, rail and power generation industries have chosen us as their solutions partner because of our innovative attitude towards individual challenges and commitment to continual improvement.