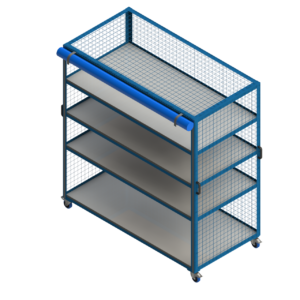

Mobile Modular Storage Racking Trolley

Mobile Modular Storage Racking Trolley

Scope: Provide mobile racking to global aerospace manufacturer. The required racking will be utilised during a strip and build maintenance process in an ‘off-wing’ facility. The racking needs to provide none metal to metal contact and allow components to be…

Read More

Protecting manufacturing components is not just about safeguarding physical assets; it’s a strategic approach to maintaining quality, reducing costs, ensuring compliance, and optimising the overall efficiency of the manufacturing process.

Scope:

Provide mobile racking to global aerospace manufacturer. The required racking will be utilised during a strip and build maintenance process in an ‘off-wing’ facility. The racking needs to provide none metal to metal contact and allow components to be secured when being stored.

Solution:

Manufacture component racks. Approx. dimensions of unit: 1860m (L) x 950mm (W) x 2000mm (H). The racks consist of a fully welded framework manufactured from 50 x 50 x 3mm mild steel angle, the framework features 4 shelves and have 50 x 5mm mild steel flat supports on each shelf.

The back, top and sides of the unit manufactured with 2″ squared mesh panels fully welded to the frame. Each shelf will have an 18mm thick plywood base fixed to the steel framework and a 3mm thick PE300 plastic drop in top. To include rubber edging on the shelves as requested. The framework is assembled with 2 x bridge handles on either side.

The trolley is completed with a PVC front cover spanning the whole width of the trolley and secured by straps.

The trolley will run on 100mm diameter castors, all 4 wheels being swivel with brake, for the full range of manoeuvrability. Each shelf will hold 50kg.

At Acres Engineering we manufacture products of this nature in many shapes and sizes with a multitude of features. These wheeled racks are mobile storage solutions designed to organise and store various components, equipment, or materials. These racks typically consist of a frame or structure with wheels attached to the bottom, allowing easy mobility and transport within a workspace. They are commonly used in industrial settings, warehouses, laboratories, and other environments where efficient organisation and accessibility of components are essential.

Key features of wheeled racks for components may include:

- Mobility: The presence of wheels allows these racks to be easily moved from one location to another, facilitating flexible and dynamic storage arrangements.

- Adjustable Shelves: Many wheeled racks have adjustable shelves to accommodate components of different sizes. This flexibility enables users to customise the storage space based on their specific needs.

- Durability: These racks are often constructed from sturdy materials such as metal or heavy-duty plastic to withstand the weight of components and provide long-lasting durability.

- Versatility: Wheeled racks can be designed for various purposes, such as holding electronic components, tools, parts, or other items. Some racks may include features like bins, dividers, or hooks to further enhance organisation.

- Space Efficiency: Wheeled racks are designed to maximize storage in limited spaces. They are often compact and can be easily maneuverered into tight spaces when needed.

- Locking Mechanisms: Some wheeled racks come equipped with locking mechanisms to secure components during storage or transport, providing an added layer of security.

- Customisation Options: Depending on the manufacturer, wheeled racks may offer additional customisation options, such as different sizes, colours, and configurations to meet specific user requirements.

These racks play a crucial role in improving workflow efficiency by making it easier to transport and access components, reducing the time and effort required to retrieve or store items. They are especially valuable in settings where frequent movement and reorganization of components are necessary.

Why is it important to look after your components and/ or products?

Protecting manufacturing components is crucial for several reasons, as it directly impacts the overall efficiency, quality, and success of the manufacturing process.

Here are some key reasons why it is important to protect manufacturing components:

- Preservation of Quality: Manufacturing components are often precision-engineered and designed to specific tolerances. Any damage or contamination can compromise their integrity and functionality, leading to defects in the final products. Protecting components helps maintain their quality and ensures that they perform as intended.

- Cost Reduction: Replacing damaged or defective components can be expensive in terms of both time and resources. Protecting components reduces the likelihood of damage during handling, storage, or transportation, ultimately saving costs associated with replacements and rework.

- Minimising Downtime: In manufacturing, downtime can have significant financial implications. When components are damaged, production lines may need to be halted for repairs or replacements, leading to delays in product delivery. Protecting components helps minimise the risk of downtime and keeps the manufacturing process running smoothly.

- Ensuring Consistency: Consistency in the quality of manufactured products is vital for customer satisfaction and brand reputation. Protected components contribute to a more predictable and consistent manufacturing process, leading to a higher likelihood of producing products that meet or exceed quality standards.

- Compliance with Regulations: Certain industries and products are subject to strict regulations and standards. Protecting components ensures that they meet these regulatory requirements, helping manufacturers avoid legal issues and ensuring that their products are safe and compliant.

- Optimising Efficiency: Well-protected components are easier to handle, store, and transport. This optimisation of logistics and handling processes contributes to overall manufacturing efficiency. It also reduces the risk of errors and accidents that can occur when working with damaged or compromised components.

- Enhancing Long-Term Reliability: Manufacturing components are often designed for durability and reliability. Protecting them from environmental factors, such as moisture, dust, or temperature fluctuations, helps ensure that they maintain their performance characteristics over time, contributing to the long-term reliability of the final products.

- Supply Chain Resilience: Protecting components is essential for maintaining a robust and resilient supply chain. Unprotected components are more susceptible to damage during transit or storage, which can disrupt the entire supply chain and lead to delays in production.

In summary, protecting manufacturing components is not just about safeguarding physical assets; it’s a strategic approach to maintaining quality, reducing costs, ensuring compliance, and optimising the overall efficiency of the manufacturing process.

What more reasons do you need, speak to us today and let’s work together to create the best solution for you. It’s an investment you will not regret.

Project REF: AD-965-2016-02-4 / 12127-P1

Acres design and manufacture lots of different trolleys.

We also manufacture access platforms, jigs and fixtures and many other types of product.

Talk to us today about your requirements: [email protected] / 01332695240 / Contact Us Form

Want to know more about Acres Engineering?

Check out our latest blog posts.

We post about our support of the Armed Forces, STEM and Charity.

We offer a range of information guides.

We make it easy to engage with us, we are approved on: JOSCAR / AVETTA / COUPA / SAP ARIBA / DEEPSTREAM….you can download our BSI / Insurance certificates here.

Have a design and development project you want the Acres team to look at? Can’t see what you want? Need something different?

Acres Engineering is established as a leader in delivering bespoke creative engineered solutions. Many OEM’s and tier one/ two suppliers in aerospace, automotive, rail and power generation industries have chosen us as their solutions partner because of our innovative attitude towards individual challenges and commitment to continual improvement.