Manifold Jig

Manifold Jig

Solution: This jig was designed to assist our client during their assembly process. Our client is the world leading manufacturer of construction and mining equipment. This particular jig will be used to secure a manifold in place, whilst hoses will…

Read More

Solution:

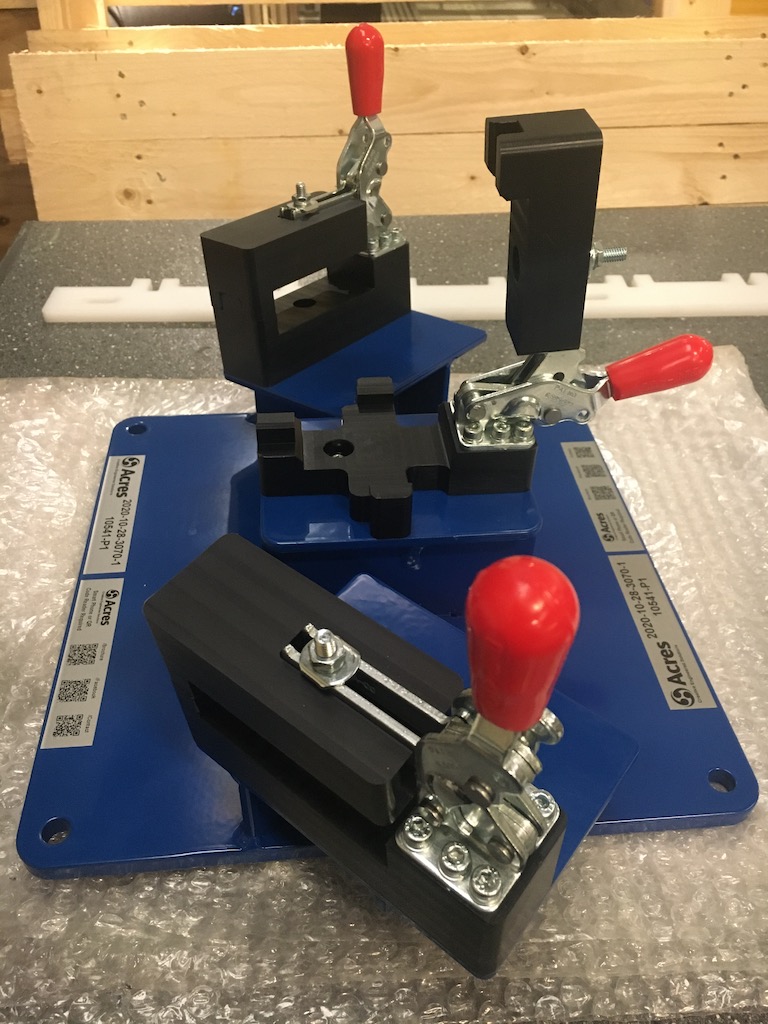

This jig was designed to assist our client during their assembly process. Our client is the world leading manufacturer of construction and mining equipment. This particular jig will be used to secure a manifold in place, whilst hoses will be fitted by the operator. Due to this, a key success factor for this project, was to ensure the hoses are help a specific position so it could be fit on the final position.

The client specified; the jig must be able to withstand a torque of 110Nm during assembly operations. The jig also needs to keep the elbows on the desired position with an accuracy of +/- 1 degree. To ensure the position of the manifold is achieve, Acres manufactured 6 bespoke Nylon blocks. The clamping was assisted by using high quality toggle clamps with an integrated safety level, each clamp was tested to ensure it can withstand 300Kg of force. The product was powder coated to the clients requested colour and delivered within the lead time specified. Acres also spent time on-site during delivery to test the jig and determine if any minor adjustments would be required. Acres Engineering are experts are designing and manufacturing production support equipment such as Jigs, enhancing Lean manufacturing within a production environment. If you have any enquiries, please don’t hesitate to contact us.

Project REF: AD-1856-2020-11-1 / 10541-P1

We have lots of different jigging solutions available for numerous applications. Take a look at a previous solutions here

Have a design and development project you want the Acres team to look at? Can’t see what you want? Need something different?

Acres Engineering is established as a leader in delivering bespoke creative engineered solutions. Many OEM’s and tier one/ two suppliers in aerospace, automotive, rail and power generation industries have chosen us as their solutions partner because of our innovative attitude towards individual challenges and commitment to continual improvement.